About VaporTech: A Leading Manufacturer of Thin-Film Deposition Systems

A Trusted Partner

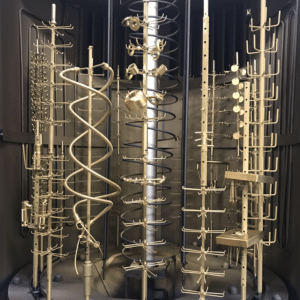

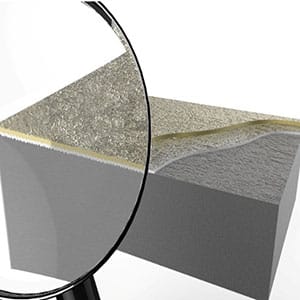

VaporTech designs, builds, and services thin-film coating equipment that deposits PVD and DLC coatings to make your great products even better. We’re committed to what we do because we know that a product’s finish instantly communicates its quality and emphasizes a brand’s commitment to quality and value. For more than 30 years, our PVD coating equipment has been helping customers apply beautiful and durable hard coatings that enhance and differentiate the look, feel, and performance of home hardware, medical devices, automobiles, industrial tooling, consumer electronics, sporting goods, and many other products. We are based in beautiful Longmont, Colorado, with global sales, service, and support.

Optimized for your needs

Your product is one of a kind, and your thin-film coating should be too. Do you need functional properties or a color match? Coating optimization gives you the perfect solution.

We’re in

this together

When you purchase a VaporTech thin-film deposition system, you get high-quality equipment and comprehensive services. We support you with ongoing maintenance, parts, service, and upgrades.

What sets VaporTech apart?

Trusted by major brands around the world.

Pre-installation support machine installation, training, and service.

Proprietary LTAVD® (low temperature arc vapor deposition) process.

Proprietary RAAMS™ high-density thin film process.

Versatile vapor deposition systems for surface finishing with integrated cathodic arc and sputtering capabilities.

Solid corporate foundation as a proud division of Masco Corporation (NYSE: MAS).

Ongoing investment in research and development to continue providing robust, cost-effective systems and desired finishes.

Frequently asked questions

What is PVD coating? How does it work? What are the benefits? Answers to top 10 questions.

DID YOU KNOW?

Eight major applications for PVD coatings are:

- Automobile

- Cutting tools

- Architectural hardware

- Medical devices

- Molds & dies

- Engineered components

- Firearms

- Knives

- Consumer goods

Where do you want to go next?

What’s going on?

Learn about upcoming industry events and news.

Get answers

Get answers from a VaporTech specialist.