Thin-Film Deposition

/ˈTHinˌfilm depəˈziSH(ə)n/

noun:

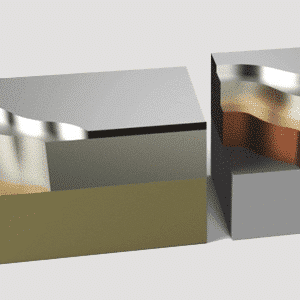

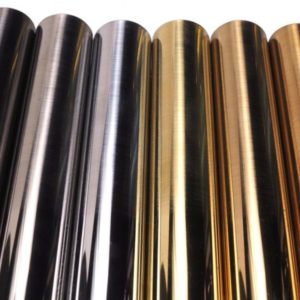

A vacuum process using an energy source to vaporize material and deposit— atom by atom—an ultra-thin layer onto a part’s surface. The coating can change the component’s surface properties, including the color, wear resistance, and friction coefficient.

Physical Vapor Deposition Equipment Manufacturer

We Are Vapor Deposition Experts

Make your great products even better with one of the world’s top PVD and PE-CVD machine manufacturers. Our state-of-the-art deposition systems combine flexibility with consistency. Engineered to deliver excellent color uniformity and remarkably even deposition rates, VaporTech vapor deposition machines are used worldwide in a multitude of industries.

Our equipment applies a wide range of PVD coatings and Diamond-Like Carbon (DLC) coatings produced using plasma-enhanced chemical vapor deposition (PE-CVD). Industries include:

- Automotive coatings for engine/drivetrain components including fuel injectors, gears, cylinders, piston rods, valves, bearings, and fasteners, as well as interior & exterior trim.

- Cutting tools, including end mills, slab mills, hobs, inserts, and cutters.

- Medical devices include orthopedic implants, plates, screws, tapers, guidewires, and surgical tools. Dental applications include dental implants, burs and drill bits, drills, and dental instruments.

- Home hardware and products in a wide array of colors, including kitchen and bath fixtures, door and window hardware, and other home products.

- Molds and dies for forming and molding, including dies, extruding dies, punches and pins, rolls, molds, and inserts.

- Precision components include compressor rotors, bearings and casings, rods, pistons, gears, valves, and more.

- Firearms components include triggers, sights, frames, muzzles, barrels, and metal framings.

- Knives, for added durability and a smooth finish on high-quality knives and blades.

- Ask us about more applications!

We Are Versatile

As a leading physical vapor deposition equipment manufacturer, we are continually innovating. Our new VT-i™ series of machines can deliver multiple coating technologies, including diamond-like carbon (DLC), from a single system. Best of all, the VT-i series has models right-sized for any operation.

The Benefits of In-House Vapor Deposition Equipment

Simplify

Simplify your supply chain process by coating your products in-house.

Reduce costs

Reduce manufacturing costs with a low coating cost per part.

Custom Colors

Develop new colors or functional coatings to differentiate your product from the competition.

Reduce impact

Reduce your environmental impact with a thin-film process that does not require hazardous chemicals.

Customer testimonials

The Vapor Technologies, Inc., equipment has been our go-to workhorse for production on a daily basis… It can take the daily throughput of production without compromising quality or dependability.

Since installation of the VT-3000 coating system, we have successfully reduced customer costs, shortened lead times, improved quality, reduced shipping and handling costs, improved ease of scheduling production runs, and improved customer relations.

What is

PVD coating?

How does vacuum deposition work? What are the benefits? Get the answers in our FAQ.

VaporTech PVD & DLC coatings

Discover new decorative and performance thin-film coating options that improve your parts and products.

Physical Vapor Deposition Equipment Manufacturer

Our team is here to help your company. Contact VaporTech today to learn more about our systems and why we are the best choice in vapor deposition equipment for companies of all sizes and budgets.

Understanding thin-film coatings

Basic information.

Get answers

Get answers from a VaporTech specialist.