2 min read

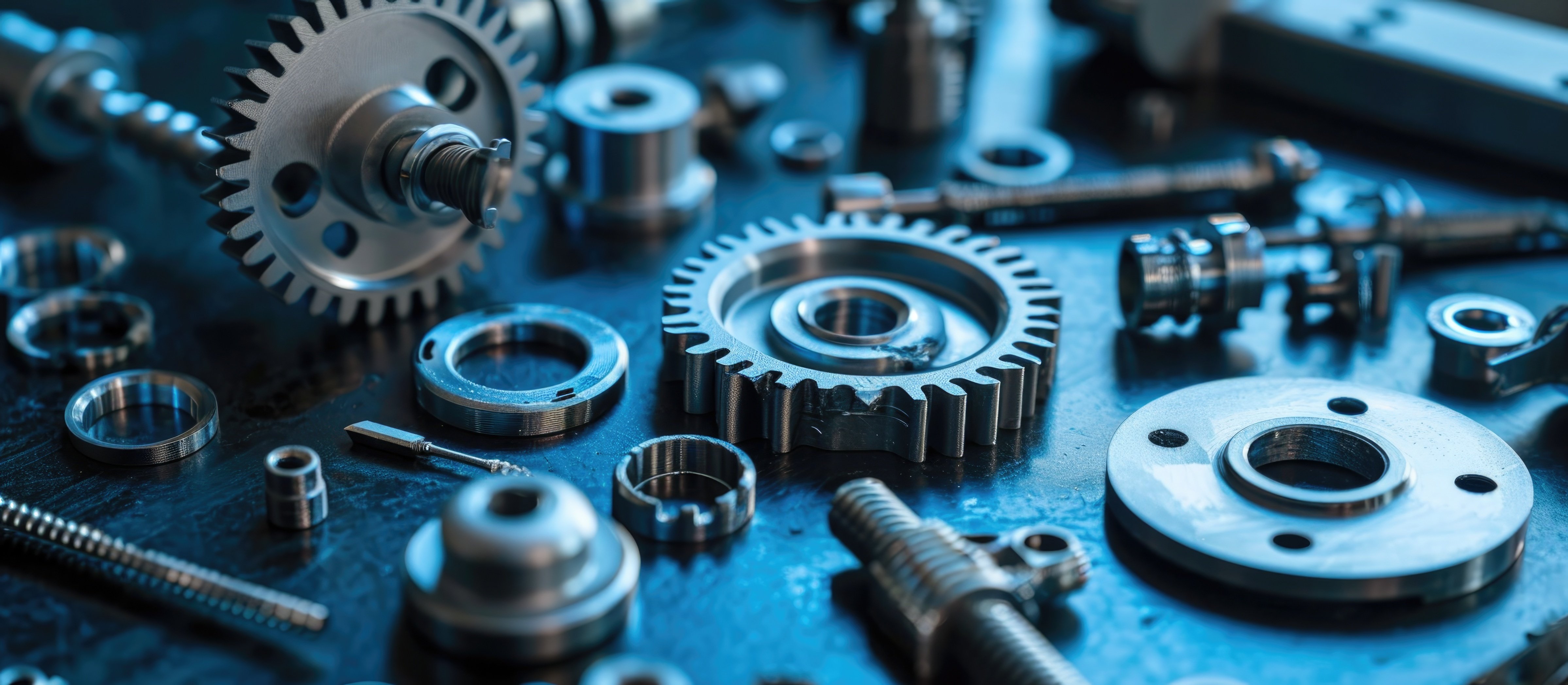

People often associate PVD coatings with finishes applied to metal substrates, such as drill bits, molding dies, consumer products (faucets and door hardware), etc. However, PVD coatings have long been used to coat plastics. This approach p...

Read More