PVD & DLC Coating: One System, Multiple Coating Types [video]

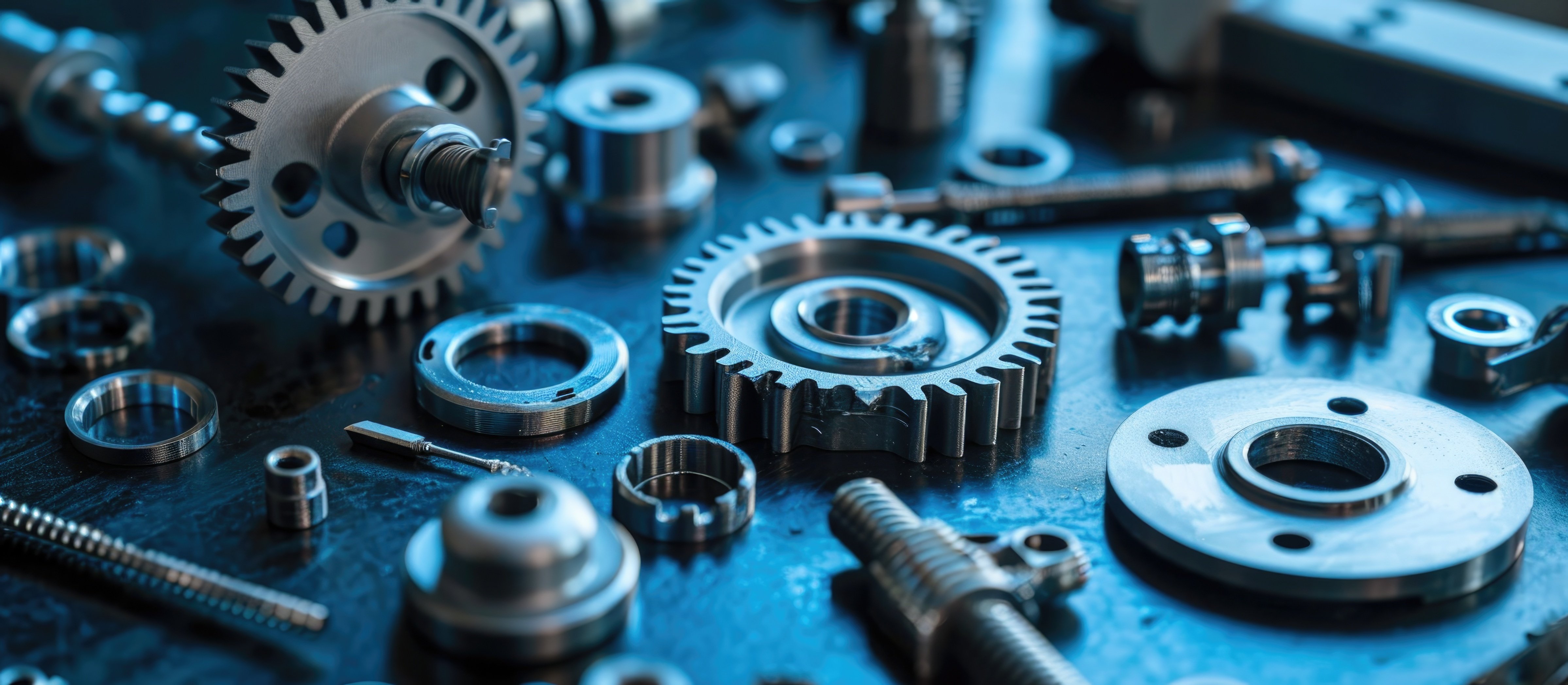

Are you hoping for a single machine to deposit both your physical vapor deposition (PVD) and diamond-like carbon (DLC) finished parts? All VaporTech thin-film deposition systems are capable of PVD and DLC coating in the same chamber, and our VT-1500i™ system coats using both cathodic arc and sputtering technologies. Coat all your parts using different recipes and source materials with only one investment from the company supplying manufacturers worldwide for 25 years. Our PVD coating systems are manufactured in Longmont, Colorado, and installed in operations worldwide. Contact us today at (303) 652-8500 (or fill out the contact form) to use one of our PVD and DLC coating systems! Go to our FAQs to get answers to our most frequently asked questions about PVD coatings and DLC coatings! We’ve put together a short video to explain (text follows).

How to Coat with PVD & DLC in the Same Chamber

Do you need both PVD & DLC coatings on your products? Do you use a coating service company because bringing two different coating machines in-house isn’t an option?

Introducing VaporTech VT-Series Coaters: thin-film vacuum coating systems that do it all (in one chamber)

- Coat your PVD products and remove them from the chamber.

- Perform a minimal setup change.

- Enter the right recipe.

- Load your DLC parts into the chamber.

- Push the Start button. You can easily switch back and forth between PVD and DLC coatings as needed. But that’s not even the best news! …which is that VT-Series coating machines are:

- Right-sized

- Affordable

- Easy to implement & operate

Recent posts

PVD Coating Machine Case Study: Faucet Manufacturer Improves ROI With VaporTech Coating Machine

Our DLC Coating Machines Produce Highly Targeted Functional DLC Coatings