Top 3 Reasons to Invest in the VT-3000i PVD Coating System

You already know that PVD (physical vapor deposition) coatings on products make them look better, function better, and last longer. That’s why VaporTech has designed the VT-3000i™ PVD coating system to help you easily add coating capability to your operations. This machine is a reliable workhorse as a PVD and CVD coating system. It's our largest system, capable of coating parts up to 48 inches, with a fast pumping speed, high loading volume, and production throughput.

1. Smaller footprint

In the past, customers needing a thin-film coating system had to reserve a lot of manufacturing space to install them. The VT-3000i system takes up less floor space, reducing the machine footprint by 40% compared to earlier systems.

2. Easy to install, operate, and maintain

Our commitment to service and support means we built this machine for ease of installation, operation, maintenance, and service. The system offers:

- Excellent reliability.

- Common fittings and feed-throughs.

- Operation and maintenance ergonomics.

- Remote-access capability for troubleshooting and configuration.

- Simplified controls: fewer gauges and controllers that require calibration.

These features improve the machine's reliability and make it easier to maintain. System installation and annual maintenance activities take less time, meaning less downtime and more time for production.

Contact us today to find out how you can start making your products better using the VT-3000i system’s coatings, which are optimized for your application.

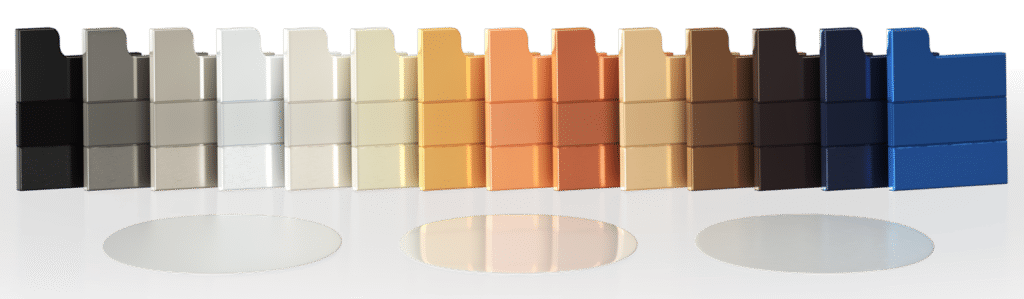

3. Great industrial and consumer product coatings

Our unique coating capabilities improve the value of customers’ products. The VT-3000i system can deposit a wide range of materials using physical vapor deposition (PVD) or plasma-enhanced chemical vapor deposition (PECVD), used for our diamond-like-carbon (DLC) coatings. It coats temperature-sensitive substrates using a unique low-temperature arc vapor deposition technology (LTAVD®). These coating technologies deposit a wide range of metallic colors, from chrome through black to gold, brass, nickel, or bronze, and an array of functional coatings. Our equipment serves manufacturers in many industries, including automotive, cutting tools, engineered components, architectural hardware, medical devices, molds & dies, firearms, blades, and others.

Recent posts

Hybrid PVD Machine Gives You Multiple Coating Options

How a PVD Coater – and the PVD Process – Work: VT-1500i™ System VIDEO