Increase Implant Longevity with Biofunctional Dental Implant Coatings

The benefits of TiN and DLC biofunctional dental implant coatings

“Increase Dental Implant Longevity with Bio-functional TiN & DLC Coatings” is an expert article featured in Medical Device Briefs. Written by VaporTech® R&D scientist Ganesh Kamath, Ph.D., this informative piece about bio-functional dental implant coatings delves deep into research showing how titanium nitride (TiN) and diamond-like carbon (DLC) coatings can increase the life of dental implants. Although artificial dental implants are the most trusted solution for mature tooth loss, they can and sometimes do fail. Kamath found that TiN and DLC coatings, applied correctly, can increase dental implants’ longevity and value. These coatings protect the abutment-implant interface from higher friction sources, abrasive wear, and fatigue fractures.

This figure shows the implant abutment and screw interface requirements for longevity. This includes smooth surfaces, wear resistance, load-bearing ability, biocorrosion resistance, biocompatibility, and antimicrobial properties:

Research & results

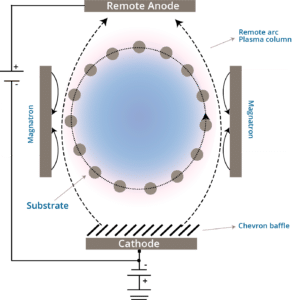

The article details the research and results showing that with this decade’s advances in PVD and CVD finishes, these coatings can now provide excellent results in biomedical applications. The VaporTech Cadence™ System was used to conduct the research. The system is designed for a range of nanostructured coatings using the patented VaporTech Remote Anode Assisted Magnetron Sputtering (RAAMS®) technology, as seen in this figure.

About VaporTech

Vapor Technologies, Inc. (VaporTech®) designs, builds, and services thin-film deposition systems that deposit PVD and PE-CVD coatings to improve products worldwide. For more than 25 years, our team of scientists and engineers has been helping customers apply beautiful and durable hard coatings that enhance and differentiate home hardware (including faucets and doorknobs), medical devices, industrial tooling, sporting goods, automotive, and many other products. We are located in Longmont, Colorado, and support our customers globally.

Recent posts

Your Top 3 DLC Coating Questions Answered

How Our Labs Develop PVD Coatings for Customer Needs