How a PVD Coater – and the PVD Process – Work: VT-1500i™ System VIDEO

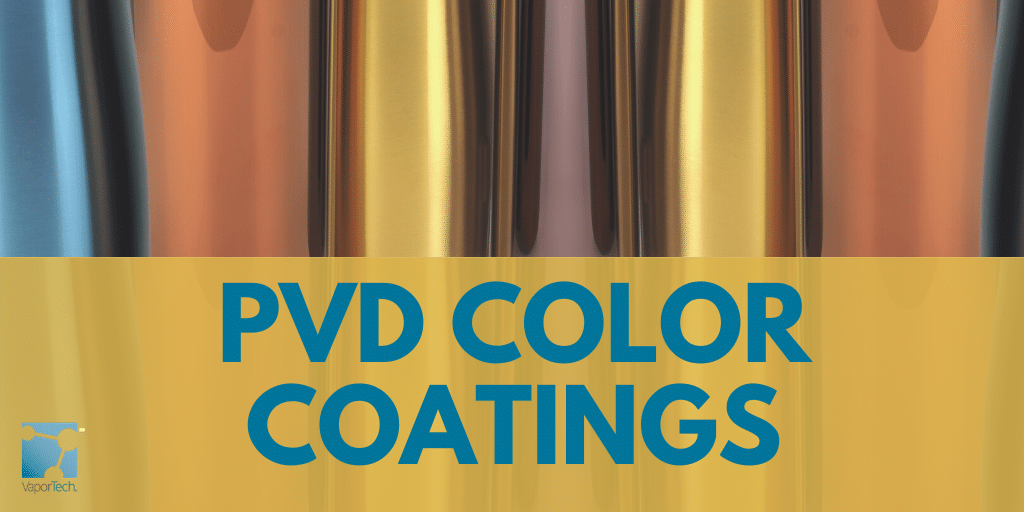

Welcome to a video overview of the VT-1500i™ PVD coating system, one of our most popular physical vapor deposition machines. This system can deposit a broad range of durable-decorative and wear-resistant performance coatings. The video gives a 360-degree tour of major system components and shows viewers how the PVD process works.

Product manufacturers use this PVD system to deposit metal-based or diamond-like carbon coatings on many products, including durable consumer goods, transportation and automotive components, medical devices, and industrial tooling.

See the PVD process.

This video will first show the significant coating equipment subsystems and run a PVD process. The VT-1500i PVD coater consists of several primary subsystems, which are detailed in the video. Second, you can watch a PVD process from parts racking and loading through the process (see image on left) and finished part unloading.

About Vapor Technologies (VaporTech®)

VaporTech physical vapor deposition (PVD systems) are designed for surface finishing with integrated cathodic arc, diamond-like carbon (DLC), chemical vapor deposition (CVD), and/or sputtering capabilities. We provide complete installation, training, engineering, and service. We’re proud of our ongoing investment in research and development to provide desired finishes.

VaporTech PVD coaters are trusted by major brands around the world. We have a solid corporate foundation as a proud division of Masco Corporation (NYSE: MAS).

Recent posts

Hybrid PVD Machine Gives You Multiple Coating Options

1 System, 2x Options for PVD Coating & Specialty Finishes