Sputtering vs. Cathodic Arc: Which Physical Vapor Deposition Process Should You Use?

Physical Vapor Deposition (PVD) is a general term used to describe several thin-film coating processes. Evaporation, sputter deposition, electron-beam evaporation, ion beam, pulsed laser, and cathodic arc are examples of PVD processes, with cathodic arc deposition and magnetron sputter coating systems playing key roles in decorative and functional industrial applications. Below, we compare both technologies.

PVD coating basics: what cathodic arc deposition and magnetron sputtering have in common

- Both use a solid source (called a target) and different inert and reactive gases to deposit thin films.

- Both are performed in a vacuum and use ionized species (plasma) to remove material from the target.

- Both can produce thin-film coatings used in decorative and/or functional applications.

- Both processes can make nitrides, carbides, oxides, and more complex compounds.

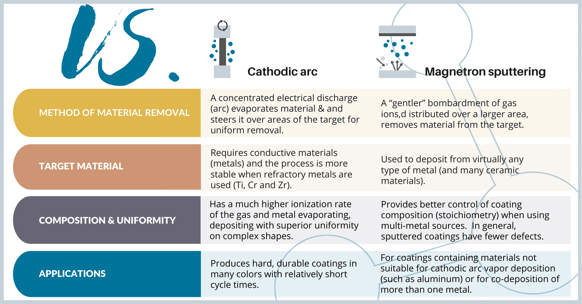

Comparison: cathodic arc vs. sputter coating (hint: The “better” method depends on your coating requirements)

Have questions about magnetron PVD sputtering equipment? Contact us today to get more information.

Need something different? Vapor Technologies has 2 new solutions:

1. RAAMS® Technology: More than traditional magnetron sputtering

When a functional application requires a thick coating with superior mechanical properties, RAAMS technology offers a unique solution that other sputter coaters can’t duplicate. RAAMS technology is an industrial-grade solution for lower ionization rates than conventional sputter coating machines and is excellent for coating tooling and high-performance engine components. RAAMS technology uses an independent electron source to exponentially increase the ionization of gas and metal ions inside the deposition chamber, boosting deposition rates, shortening coating times, and improving PVD thin-film coating density, hardness, and wear resistance. Our Cadence™ machine uses RAAMS technology to deposit films tens of microns thick.

2. Dual-method coatings: Cathodic arc deposition + sputtering = unique specialty coatings

Sometimes, applications require unique specialty coatings a sputter coater or cathodic arc physical vapor deposition system cannot provide independently. To tackle those hard-to-achieve hybrid coatings, use the VaporTech VT-1500i PVD system with cathodic arc PVD and magnetron sputter deposition coating machine capabilities in the same machine. Learn more about our PVD & DLC coating system with optional magnetron sputtering.

Contact us for more information by calling (303) 652-8500.

Recent posts

Your Top 3 DLC Coating Questions Answered

Our DLC Coating Machines Produce Highly Targeted Functional DLC Coatings