Why use physical vapor deposition (PVD) to create functional coatings?

Since civilization started creating tools, we learned that having properties on the surface that were different from the bulk of the tool often improved its properties. A well-documented example is the development of the steel sword. Early warriors learned that a very hard/sharp steel without some flexibility resulted in a fragile, easy-to-break sword.

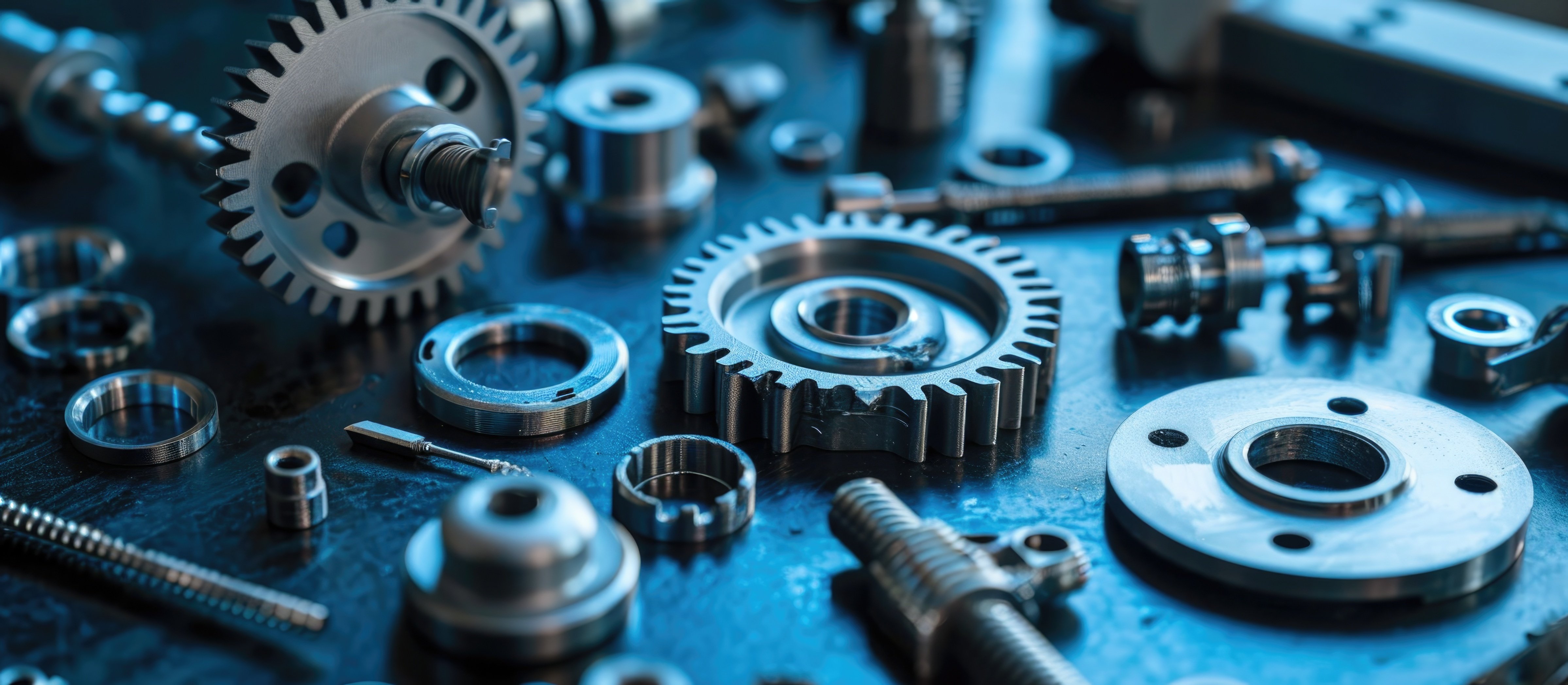

We use many processes to treat the material to be internally “flexible” but externally hard and sharp. In today’s demanding world, there are many reasons why product manufacturers want to change the external/surface properties of the object/tool without modifying the internal characteristics. These intended surface properties are often related to friction and wear.

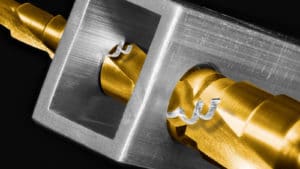

One practical example is the cutting tools used in machining. These tools are required to withstand significant impact during operation, which is why metals, usually tougher than ceramics, are used. However, metal–even treated metal–may not have the cutting and/or wear resistance characteristics needed for the job, and that is why thin-film coatings are the ideal solution. Processes such as low-temperature PVD provide hard ceramic-like finishes that adhere well to the metal. Because they are very thin, these coatings do not affect tight manufacturing tolerances.

Want to learn more about functional PVD coatings? Contact us today to learn more!

Why is tribology critical to manufacturing?

Back in the 1960s, a group of UK scholars set out to understand how to improve the efficiency of industrial manufacturing. The group, led by P. Jost (1966, 1976), discovered that the UK could save approximately 500 million British pounds annually by reducing friction and wear. Dr. Jost pointed out the need to better understand this complex problem. He coined the word “Tribology” for the science combining the knowledge of physics, chemistry, material science, and mechanical engineering to understand this phenomenon better. Since then, every time a company must solve complex wear and/or friction problems, it has entered the world of tribology! This specialized discipline has expanded and grown, so many companies, universities, and research institutes have developed tribology laboratories. There are even established and well-known societies around the world studying this field. One of the largest is the Society of Tribology and Lubrication Engineers (STLE). Tribology has so many applications in diverse industries that we have developed specializations for making specific coatings.

Thin-film and tribological coatings

Thin films can modify the superficial properties without affecting the basic bulk material characteristics. These functional coatings usually change both the hardness and toughness of the surface. They can also be tailored to dramatically improve durability, friction, and/or wear characteristics. Since these thin films include many types, they can be selected according to the application. Tribology knowledge and the ability to test the performance of these coatings are critical for successfully developing the ideal solution for any specific application.

Why VaporTech?

At Vapor Technologies, Inc. (VaporTech), we have extensive knowledge about the deposition of thin and durable films, experienced professionals who have worked solving tribological problems in many industries, and the testing and characterization tools that allow the development of specialized films for many industries. Every system we sell comes with custom coating development unique to your product, improving part performance without design impact and making your great products even better. Contact us today for more information!

Recent posts

Dark Black, Purple, and Rainbow PVD Coatings

All That Glitters is Not Gold—But It May Be Gold PVD Coating