Exceptional PVD Coating Solutions for Industrial & Consumer Applications

Use VaporTech® PVD & DLC coating systems to enhance product durability, value, and performance.

Physical Vapor Deposition Equipment Manufacturer

Headquartered in Colorado, Vapor Technologies, Inc., (VaporTech®) is one of the world’s leading physical vapor deposition (PVD) equipment manufacturers.

Equipment

- VaporTech is one of the world’s leading physical vapor deposition (PVD) equipment manufacturers. Our equipment also produces diamond-like carbon (DLC) coatings. Both processes can be run in the same chamber.

- We work with clients of all sizes in multiple industries. Our V.MAX1500™, VTi-Series ™, and Cadence® Systems enable manufacturers to choose the perfect system for their size, industry, and application.

Coatings

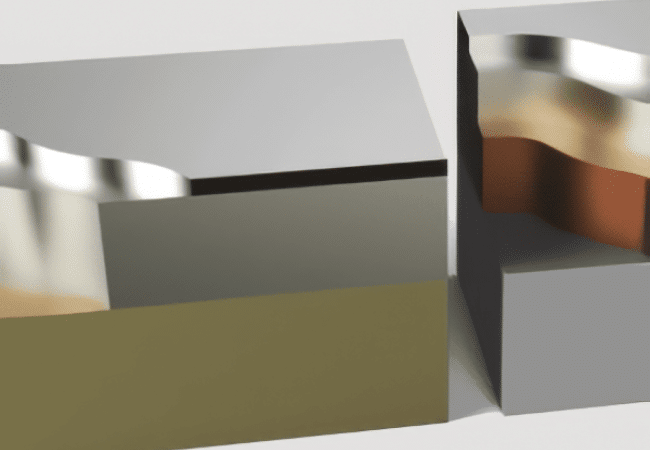

- Our coatings include functional performance coatings optimized for required properties such as hardness and lubricity. We offer a rainbow of PVD color coatings for durable/decorative applications.

- Our scientists optimize coating recipes for your new physical vapor deposition machine. We thoroughly test all recipes to perfect their functional properties and appearance without impacting performance or critical dimensions.

What is PVD coating?

How does vacuum deposition work? What are the benefits? Get the answers in our FAQ.

VaporTech PVD & DLC coatings

Discover new decorative and performance thin-film coating options that improve your parts and products.

VaporTech coating systems

Get started with the right VaporTech machine, now including the V.MAX1500 system.

We Are Vapor Deposition Experts

Make your great products even better with one of the world’s top PVD and DLC machine manufacturers. Our state-of-the-art deposition systems combine flexibility with consistency. Engineered to deliver excellent color uniformity and remarkably even deposition rates, VaporTech vapor deposition machines are used worldwide in many industries.

The Benefits of In-House Vapor Deposition Equipment

A common misconception about purchasing PVD equipment from a manufacturer vs. using a third party for coating is that the cost of ownership is high and will negatively impact your profit margin. When you outsource, you must package, send, and wait to receive your finished products before repackaging for sale. That is assuming that the coating provider and shipping companies deliver on-time. In-house vapor deposition equipment is integrated directly into your manufacturing and QC process. This integration means you can measure coating costs per part in cents, not dollars.

Simplify your supply chain process by coating your products in-house.

Reduce manufacturing costs with a low coating cost per part.

Develop new colors or functional coatings to differentiate your product from the competition.

Reduce your environmental impact with a thin-film process that does not require hazardous chemicals.

Are you still wondering if investing in vapor deposition machines and VaporTech is the right move for your company?

Customer Testimonials

“The Vapor Technologies, Inc., equipment has been our go-to workhorse for production on a daily basis… It can take the daily throughput of production without compromising quality or dependability.”

“Since installation of the VT-3000 coating system, we have successfully reduced customer costs, shortened lead times, improved quality, reduced shipping and handling costs, improved ease of scheduling production runs, and improved customer relations.”