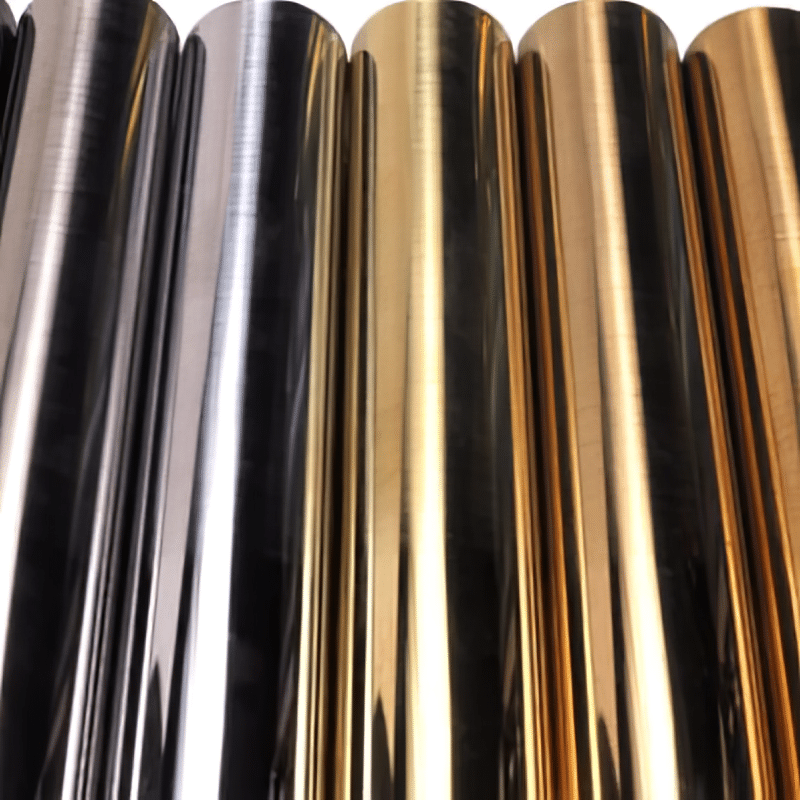

Your PVD Coating Machine Manufacturer for Functional and Durable Color Coatings

We have a right-sized PVD and DLC machine to suit your industry and differentiate your product!

VaporTech® systems deposit PVD finishes for a wide range of applications, including:

- Faucets & door knobs

- Cutting tools

- Molds & dies

- Precision components

- Automotive

- Medical devices

- Knives

- Shooting sports

Get exceptional industrial product coatings in the V.MAX1500 coating system. Learn more »

Faucets & knobs

Plumbing and cabinet fixtures in a wide array of colors, including kitchen and bath fixtures, door and window hardware, and other home products.

Automotive coatings

For engine/drivetrain components including fuel injectors, gears, cylinders, piston rods, valves, bearings, and fasteners, as well as interior & exterior trim.

Medical Devices

Include orthopedic implants, plates, screws, tapers, guidewires, and surgical tools. Dental applications include dental implants, burs and drill bits, drills, and dental instruments.

Molds and Dies

For forming and molding, including dies, extruding dies, punches and pins, rolls, molds, and inserts.

Precision Components

Includes compressor rotors, bearings and casings, rods, pistons, gears, valves, and more.

Firearms Components

Components include triggers, sights, frames, muzzles, barrels, and metal framings

Knife Components

For added durability and a smooth finish on high-quality knives and blades.

Cutting Tools

Including end mills, slab mills, hobs, inserts, and cutters.

PVD finishes coat high-end consumer items in a wide variety of industries. Some examples are:

- Surgical, dental, and medical device finishing, including hip replacements and dental implants.

- Functional (tribological) coatings for friction-bearing surfaces such as high-performance automotive engine parts and diamond-like carbon (DLC) coating for high-precision parts.

- Durable-decorative finishes for home goods, plumbing products, including faucets, sporting goods, jewelry & watches, and electronics.

- For the automotive industry, PVD/CVD engine coatings improve trim and chassis components.

VaporTech is a leading industrial PVD coating manufacturer. Our coatings improve the hardness and durability of even the toughest, heat-treated steel.

To find out if your business can benefit from our PVD coating systems, contact us today at (303) 652-8500.

Simplify

Simplify your supply chain process by coating your products in-house.

Reduce costs

Reduce manufacturing costs with a low coating cost per part.

Optimized Colors

Our coating optimization process means you get coatings to match other parts or legacy colors.

Reduce impact

Reduce your environmental impact with a thin-film process that does not require hazardous chemicals.