VaporTech® PVD Machines for Mold & Die Coatings

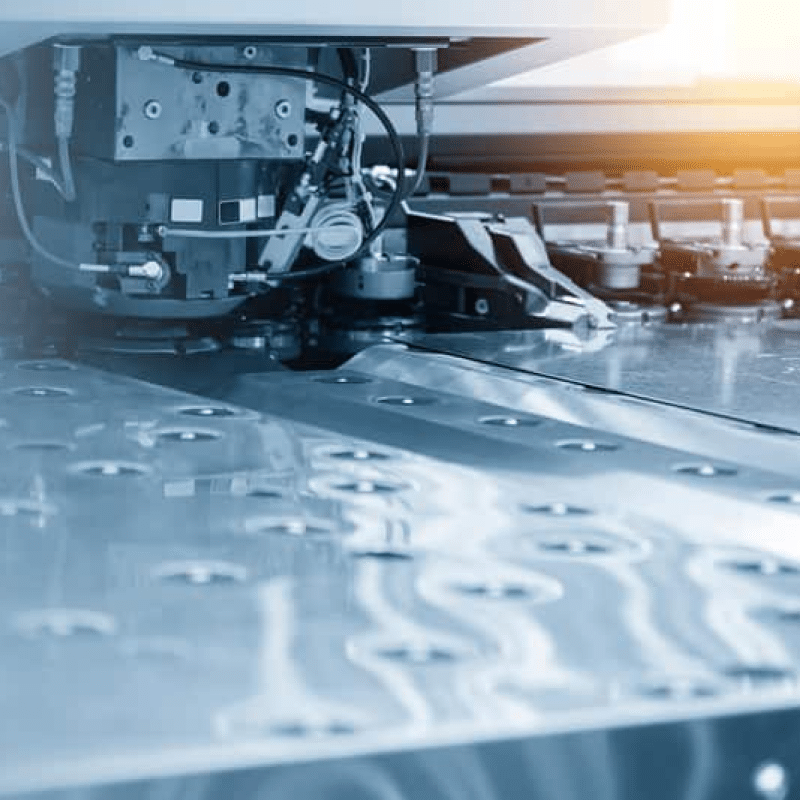

Use in-house PVD coating equipment for forming and molding, including dies, extruding dies, punches and pins, rolls, molds, and inserts.

Increase the service life of your forms, molds, and dies with high-performance functional physical vapor deposition (PVD) and diamond-like carbon (DLC) coatings.

Performance coatings

Explore the benefits of VaporTech functional thin-film coatings.

VT-1500i™ system

The VT-1500i is a compact, price competitive, high-capacity PVD coating machine with optional sputtering capabilities.

Cadence system

Quickly deposit coatings that improve your product’s wear resistance and reduce friction.

PVD coating for forming and molding offers reliability and durability

Our PVD and DLC coating systems improve forming and molding tools’ performance and durability, protect them from heavy wear, and extend their useful life. Maintain the surface of your dies, extruding dies, punches and pins, rolls, molds, and inserts. Our PVD machines for mold and die coatings allow you to choose from various thin-film coatings to suit your exact needs.

Specific PVD & DLC coatings for mold and dies

Materials used for mold and die PVD coatings include:

- Chromium nitride (CrN)

- Titanium nitride (TiN)

- Titanium carbonitride (TiCN)

- Zirconium nitride (ZrN)

- Diamond-like carbon (DLC)

These VaporTech® PVD and DLC coatings for your molds and dies add hardness and toughness, reduce friction, and provide corrosion, wear resistance, and other properties. Our experts help customers choose the most appropriate coating material and optimize it for their needs, whether for dies, extruding dies, punches and pins, rolls, molds, or inserts. Contact us today.