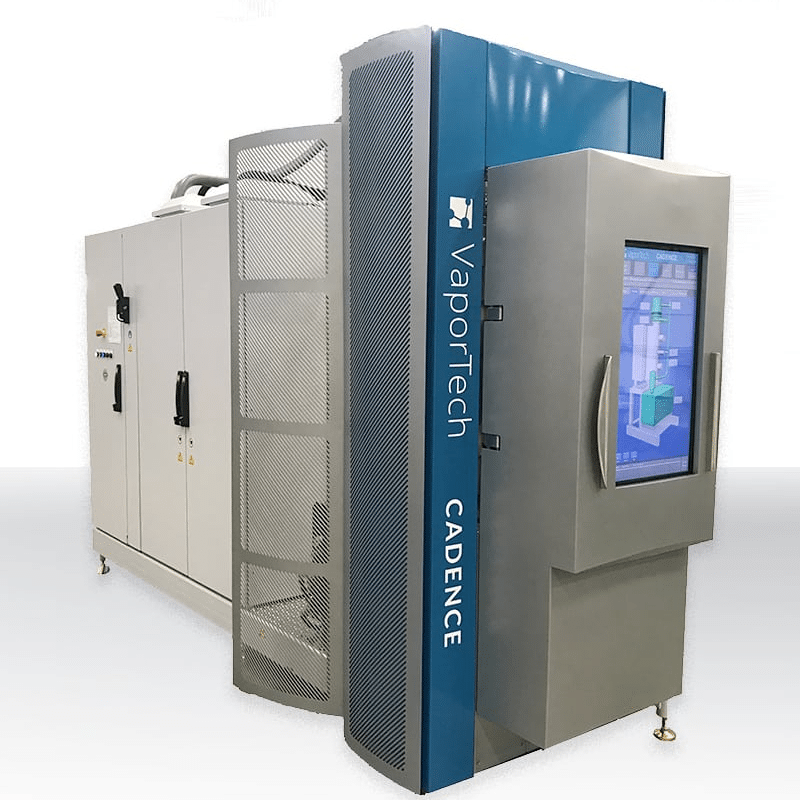

The Cadence System:

Compact, Fast Magnetron Sputtering Deposition System for Functional Coatings

The Cadence system is a compact, fast RAAMS® magnetron sputter deposition machine designed for high-performance coatings.

Cadence® magnetron coating systems excel at quickly depositing functional coatings that dramatically improve your product’s wear resistance, reduce friction, increase heat resistance, and improve product life for many industrial and consumer products.

Get exceptional industrial product coatings in the V.MAX1500 coating system. Learn more »

Using our proprietary RAAMS® (Remote Anode Assisted Magnetron Sputtering) process provides high deposition rates to shorten coating times and multiple coating sources to further increase deposition rates or deposit composite materials. RAAMS is a high-energy process that improves coating structure, hardness, and wear resistance compared to traditional PVD sputtering systems. Cadence systems are compact, fast, and easy for even smaller manufacturing operations to use and maintain.

Have questions about our magnetron sputtering systems or PVD coating machines? Give us a call at (303) 652-8500 today!

Cadence sputter deposition systems deliver.

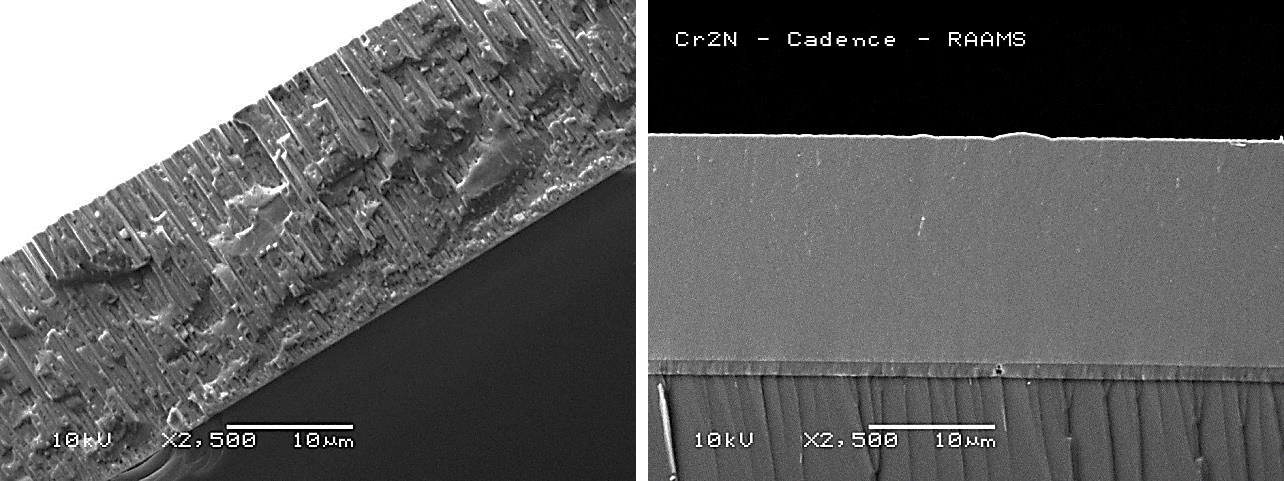

Microscopic comparison of DC magnetron sputtering coating system vs. VaporTech RAAMS coating in the Cadence system

Cadence sputter coating systems include the following key capabilities:

Compact

Small & easy to integrate into factory.

Versatile

Multiple coating technologies with various applications in one system.

Fast

Can be configured for rapid coating deposition.

| Cadence Specifications | |

|---|---|

| System capacity | |

| Coating Zone | 18 x 8 in. (45.7 x 20.3cm) |

| Loading capacity | 35 lbs. (15.9kg) |

| Size | |

| Height | 96 in. (2.4m) |

| Width | 48 in. (1.2m) |

| Depth | 150 in. (3.8m)* |

| Coating technologies | |

*Without load assist |

|

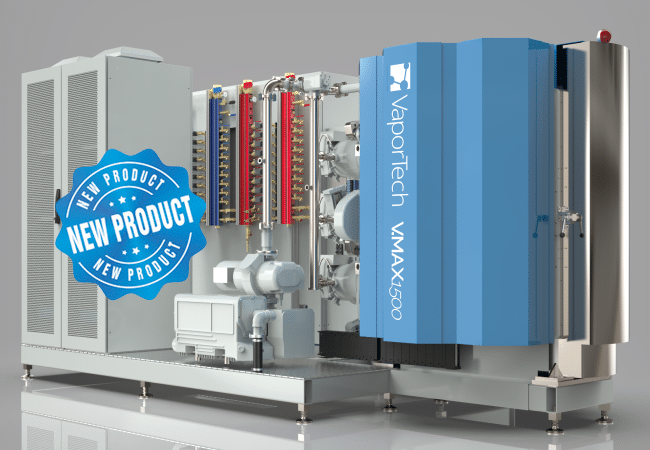

New: V.MAX1500™ system

Check out our newest PVD coater designed for industrial applications.

VT-3000i™ system

The VT-3000i is our highest-capacity coating machine for large-scale operations.

VT-1500i™ system

The VT-1500i is a compact, price competitive, high-capacity PVD coating machine with optional sputtering capabilities.

Looking for a different machine?

- Learn about the VT-1000i system, our medium-volume compact PVD and PECVD/DLC coating machine.

- Need a higher-volume option? Take a look at the VT-1500i™ system, our PVD and DLC coating system with optional magnetron sputtering.

- The VT-3000i is our largest PVD and PECVD/DLC coating system.

- Discover the V.MAX1500, a flexible industrial PVD coating system designed for versatility and efficiency in various coating applications.

How big is this coating machine?

The Cadence® system has a footprint of 3.8m x 1.2m (12.47 ft. x 3.94 ft.)

How big is the chamber?

The Cadence® system has a coated area capacity of 0.29m2 (3.12 sq ft.)

Which PVD technologies does this system have?

Remote anode-assisted magnetron sputtering (RAAMS®)

Which coating processes does this system use?

Plasma-enhanced chemical vapor deposition (PECVD)

What coatings can be applied with this coating machine?

This system applies functional zirconium, titanium, chromium, and DLC coatings.

What are the industries/applications that benefit from coatings made in the Cadence® system?

The Cadence system coats tools, tooling, automotive parts, and other precision components requiring extremely high durability.