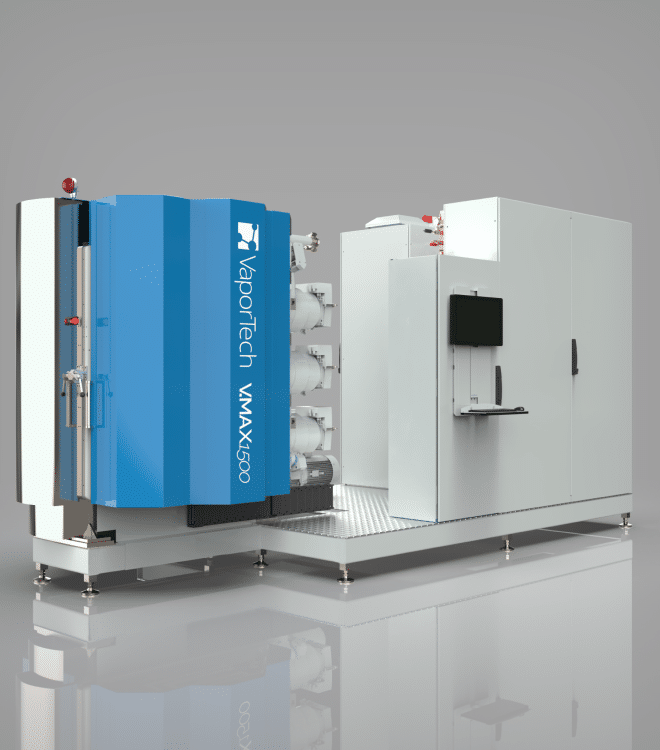

The V.MAX1500™ Flexible Industrial PVD Coating System Deposits Durable Coatings In-House

The V.MAX1500™ flexible industrial PVD coating system excels at functional, industrial applications. Industries include medical devices, engine parts, tools and tooling, dies and molds, and precision components.

The newest addition to our VaporTech® coating systems is a batch PVD coating machine designed specifically for manufacturers’ needs in industrial cutting and forming tools, precision-engineered components, automotive/aerospace parts, medical devices, and other components that can benefit from improved durability, reduced friction, and extended product longevity.

The VaporTech V.MAX1500 PVD system

- A combination of up to 6 wall-mounted cathodic arc and/or magnetron sputtering sources for ultimate flexibility and speed.

- Deposits a broad range of functional PVD coating materials—including Ti, Cr, and Zr nitrides, carbides and carbonitrides, high-temperature Al alloy coatings, and diamond-like-carbon (DLC)—all in the same system.

- Both low-temperature and high-temperature deposition options for many coatings.

- Plasma nitriding plus PVD in the same chamber.

- Fast and flexible loading/unloading with 6 to 12 rack positions on a removable turntable.

- Deposits our broad range of durable and decorative PVD colors.

The V.MAX1500 PVD and DLC coating system includes the following key capabilities:

Efficient

Faster deposition rates for shorter coating cycles.

Flexible

Multiple coatings for all your applications.

Cost

Competitive cost vs. other similar PVD coaters.

Time savings

Removable turntable for fast, flexible loading and unloading.

Service

The VaporTech® commitment to long-term relationships and comprehensive support.

Trust

The stability and reliability of a company backed by Masco, our Fortune 500 corporate parent.

The V.MAX1500 system includes:

- Modern turbomolecular vacuum pumps for excellent pumping performance and lower power consumption.

- Advanced cathodic arc, sputtering, bias, and ion source power supplies to improve coating quality and system reliability

- The compact system footprint is 2.1m x 4.8m and all components are on one skid for easier transport and a faster, streamlined installation.

- Straightforward maintenance with dual chamber doors, easy-to-remove deposition shields, and quick access to all sources for target changes.

- The most recent version of our simple-to-use VaporTech coating system software interface

- The renowned quality, reliability, applications, and service support that VaporTech has provided for the past 40 years.

V.MAX1500 system specifications | |

|---|---|

System capacity |

|

Coating area per rack | 80 cm x 25.4 cm ø (6 rack option) |

Number of rack positions | 6 standard (up to 12 optional) |

Chamber coating zone | 80 cm x 88 cm ø |

System footprint | 2.1 m x 4.8 m |

Coating technologies |

|

|

|

Available coatings |

|

|

|

VT-3000i™ system

The VT-3000i is our highest-capacity coating machine for large-scale operations.

VT-1500i™ system

The VT-1500i is a compact, price competitive, high-capacity PVD coating machine with optional sputtering capabilities.

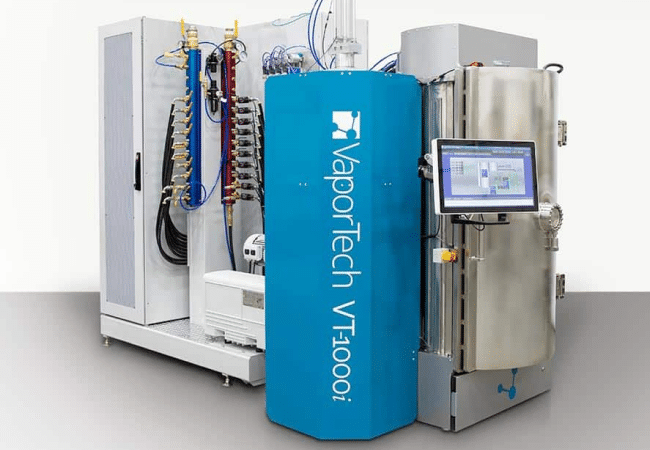

VT-1000i™ system

The VT-1000i is a compact higher-capacity system for medium-sized operations.

- Explore the VT-1000i system, a compact solution for medium-volume PVD and PECVD/DLC coating applications.

- For higher-volume needs, consider the VT-1500i™ system, offering PVD and DLC coating capabilities with an optional magnetron sputtering feature.

- The VT-3000i system is our most extensive machine, designed for large-scale PVD and PECVD/DLC coating operations.

- For a compact and rapid system tailored to specialty performance applications, the Cadence® system is an excellent choice.