VaporTech PVD Coating Machines (with PECVD/DLC Capability)

VaporTech PVD coating machines feature advanced PECVD/DLC capabilities that enhance functional surface properties and add a wide range of colors across industrial and commercial applications.

PVD coating equipment flexibility

Achieve superior functional, durable/decorative, and DLC coatings with any VaporTech system. Our PVD coating machines deposit coatings that enhance your products’ look, feel, function, and durability—without affecting critical dimensions or performance. These aren’t simply metal layers but compound materials that can be customized to be harder than case-hardened steel or more scratch-resistant than hard chrome. Coatings range from rich black to a wide choice of beautiful colors.

Get exceptional industrial product coatings in the V.MAX1500 coating system. Learn more »

Free yourself from high third-party coating costs, production delays, and quality control issues! Coat your products for less than $1 per part by bringing a VaporTech® PVD & DLC/PECVD machine in-house. Let’s get you started with the right PVD coating machine now.

VaporTech PVD & DLC/PECVD coating equipment and machines maximize product value and ROI

VaporTech offers a range of PVD & DLC/PECVD equipment designed for everything from high-volume, large-scale manufacturing to small-batch operations. When you purchase a PVD coating machine from VaporTech, you receive quality products, coating optimization, professional customer care, technical support, and even employee training.

Which of our PVD coating machines is right for you?

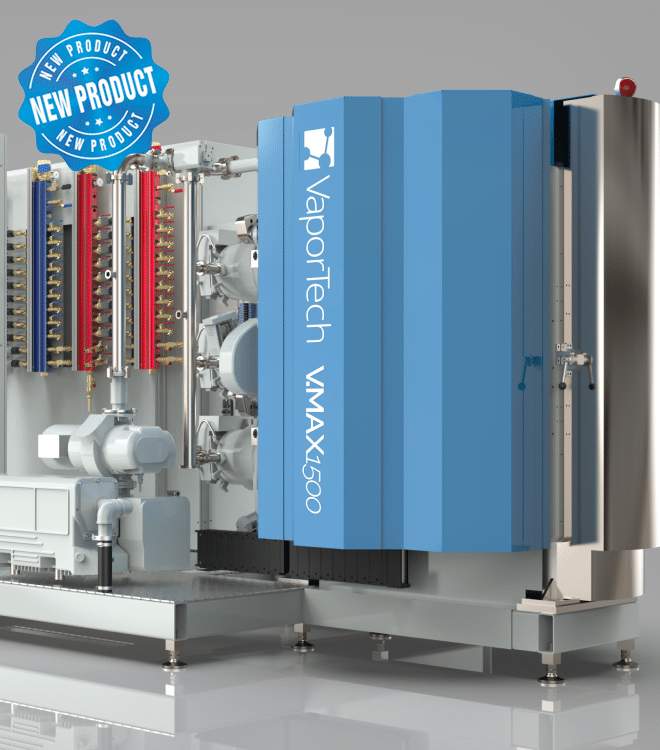

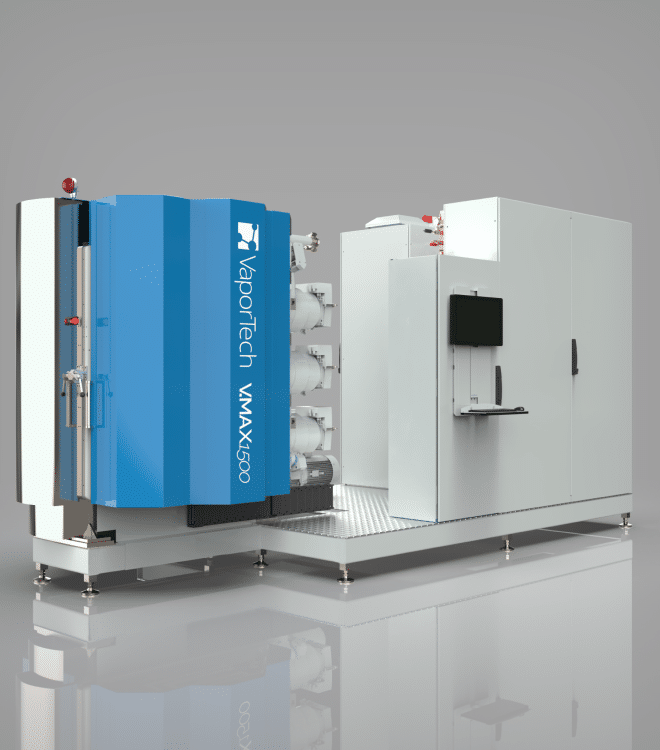

V.MAX1500 system™

Our newest machine, the V.MAX1500™ coating system, is a batch PVD coater for industrial applications in cutting and forming tools, precision-engineered components, automotive/aerospace parts, medical devices, and other components that require enhanced durability, lower friction, and longer product life span.

Advantages:

- The V.MAX1500™ system is a versatile solution with up to 6 wall-mounted cathodic arc and/or magnetron sputtering sources for optimal performance across many applications.

- A wide range of functional PVD coating materials including Ti, Cr, and Zr nitrides, carbides and carbonitrides, high-temperature Al alloy coatings, and diamond-like carbon (DLC).

- Both low-temperature and high-temperature deposition options for many coatings, depending on the application requirements.

- Plasma nitriding plus PVD in the same chamber for enhanced surface hardening and wear resistance.

- Fast and flexible loading/unloading with 6 to 12 rack positions on a removable turntable, enhancing productivity and convenience for your operations.

- Also deposits our broad range of durable and decorative PVD colors to suit your needs and meet market demands.

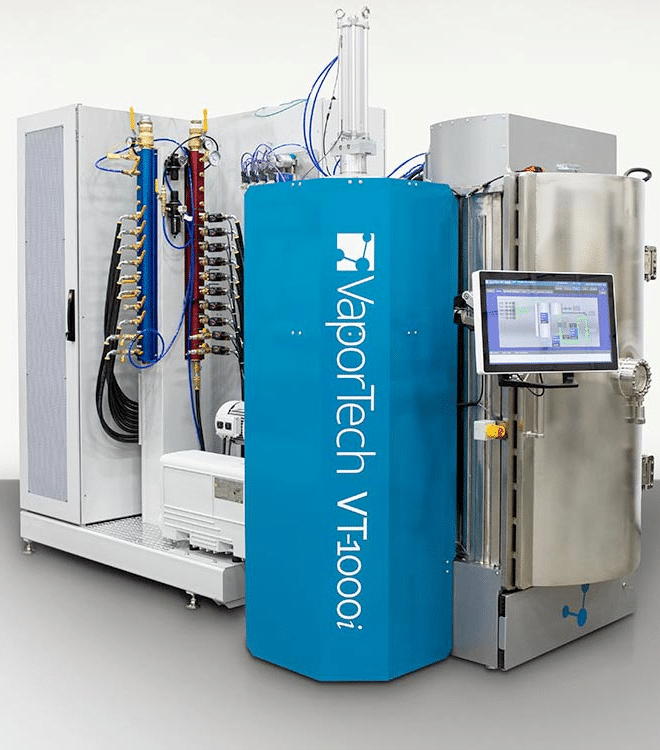

i-Series™ systems

The VaporTech VT Series offers equipment right-sized for any operation. Our PVD & DLC/PECVD equipment delivers multiple coating technologies in a single PVD coating machine. Our systems use the same chamber to produce functional, decorative, and DLC coatings. Our equipment gives you a competitive edge. The VT Series machines feature a proprietary low-temperature process suitable for coating plated plastic parts.

Applications include home hardware, plumbing products, sports equipment and firearms, tools and tooling, medical devices, automotive components, and other consumer and industrial products.

VaporTech VTi-Series PVD coating machines utilize a unique, centrally mounted coating source with parts that rotate around the perimeter of a large, actively cooled chamber. The VT-1500i™ system is now available with up to two additional magnetron sputtering sources for specialty performance coatings. The equipment is available in a range of capacities, all with a small footprint for easy integration.

Advantages:

- Multiple PVD machines, right-sized and competitively priced for medium- and high-volume manufacturing.

- Excellent color uniformity throughout the chamber for color coatings in decorative applications.

- Even coating deposition rates throughout the chamber for excellent coating thickness control.

- Some of the lowest coating temperatures in the industry are suitable for both metal and plastic parts.

- Able to coat large parts up to 122 cm (48 inches) long.

Cadence® system

The Cadence magnetron sputtering system excels at quickly depositing functional coatings that significantly improve wear and heat resistance, reduce friction, and increase the life of many industrial and consumer products. This product deposits dense, smooth coatings similar to those deposit using HIPIMS technology but with faster deposition rates. Applications include tools, tooling, automotive, and other engineered components requiring very high durability.

Advantages:

- Patented VaporTech RAAMS® technology, a high-energy process that significantly improves coating structure, hardness, and wear resistance compared to traditional sputtering systems.

- High deposition rates shorten coating times for functional applications.

- Multiple coating sources further increase deposition rates or deposit composite materials.

- This compact system is easy for smaller manufacturers to use and maintain.

- The perfect performance machine for zirconium, titanium, chromium, or DLC coatings.

Our products

V.MAX1500 system

Our newest machine coats industrial components for improved durability, reduced friction, and extended product longevity.

VT-1000i system

Our easy-to-operate mid-sized lower-temperature thin-film coating system.

VT-1500i system

Our higher capacity system with two optional magnetron sputtering targets.

VT-3000i system

Our highest-capacity, lower-temperature PVD coating system.

Cadence Systems

Our most compact, easiest-to-use, and fastest thin-film coating unit for any size operation.

DID YOU KNOW?

A typical VaporTech durable

decorative coating is less than

1/100

the thickness of a human hair, keeping

blades sharp and other product features intact.