VT-1500i™: High-Capacity Cathodic Arc System with Optional Magnetron Sputtering

The VT-1500i™ is our mid-size VTi-Series™ PVD & DLC coating system. Two optional magnetron sputtering sources deliver high-performance coatings.

The VT-1500i™ PVD & DLC coating system with optional magnetron sputtering deposits a broad range of bright and dark metallic colors as well as our diamond-like carbon (DLC) and functional, highly wear-resistant coatings.

Get exceptional industrial product coatings in the V.MAX1500 coating system. Learn more »

The VT-1500i PVD system provides high throughput but in a very compact footprint. This unique system includes both cathodic arc and optional magnetron sputtering technologies in the same machine – up to 3 PVD sources. With the ability to coat parts up to 100 cm long and 10 high-capacity racks, the VT-1500i™ is a high volume, flexible, price-competitive coating system for manufacturers and coating service providers.

Learn more about VaporTech coating systems by calling us today at (303) 652-8500.

The VT-1500i PVD & DLC coating system with optional magnetron sputtering includes the following key capabilities:

Compact

Small footprint, easy to integrate into factory.

Simple

Easy to operate and maintain with many applications.

Low cost

Low per-part coating costs.

Part sizes

Coat large parts up to 100 cm long.

Flexibility

Available with cathodic arc and magnetron sputtering technologies.

Capacity

High capacity for large operations.

| VT-1500i system specifications | |

|---|---|

| System capacity | |

| System footprint | 4.4m x 2.0m |

| Coating area per batch | 7.98 m2 |

| Number of racks | 10 |

| Rack size | 100cm x 25.4cm Ø |

| Coating technologies | |

|

|

| Coating processes | |

|

|

| Available coatings | |

|

|

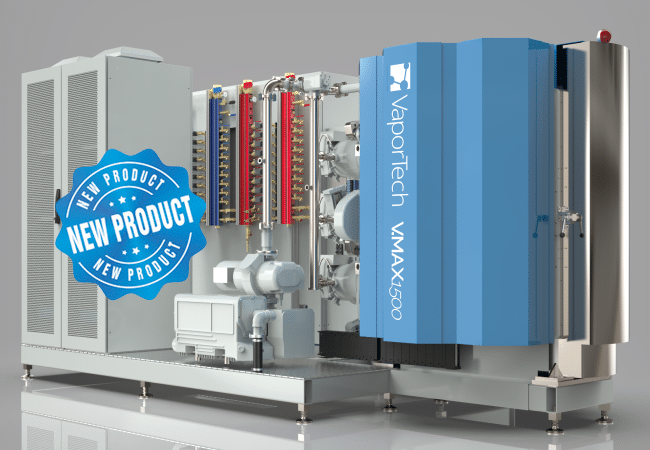

New: V.MAX1500™ system

Check out our newest PVD coater designed for industrial applications.

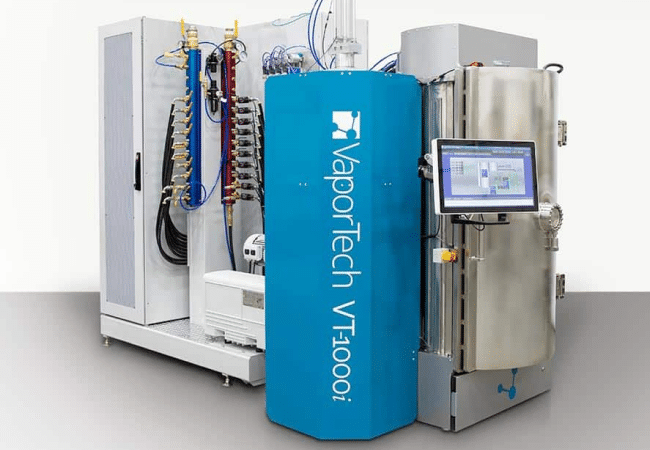

VT-1000i™ system

The VT-1000i is a compact higher-capacity system for medium-sized operations.

VT-3000i™ system

The VT-3000i is our highest-capacity coating machine for large-scale operations.

Looking for a different machine?

- Learn about the VT-1000i system, our medium-volume compact PVD and PECVD/DLC coating machine.

- The VT-3000i is our largest PVD and PECVD/DLC coating system.

- If you want a compact, fast system for specialty performance applications, check out the Cadence® system.

- Discover the V.MAX1500, a flexible industrial PVD coating system designed for versatility and efficiency in various coating applications.

How big is this coating machine?

The VT-1500i™ system has a footprint of 2.0m x 4.4m (6.7 ft. x 14.4 ft.)

The VT-1500i™ system is the mid-size model in the VaporTech® VTi Series.

How big is the chamber?

The coated area capacity is 8 m2(86.1 sq ft.).

How many racks does this PVD system have?

The VT-1500i™ system has 10 racks.

Which PVD technologies does this system have?

Cathodic arc (LTAVD®)

Magnetron sputtering

Which coating processes does this system use?

Physical vapor deposition (PVD)

Plasma-enhanced chemical vapor deposition (PECVD) to create diamond-like carbon (DLC) coatings.

What coatings can be applied with this coating machine?

This system applies pure, alloyed, or reacted zirconium, titanium, chromium, and carbon coatings.

What are the industries/applications that benefit from coatings made in the VT-1000i system?

The VT-1500i system coats industrial and consumer products, including plumbing and home hardware products (faucets and doorknobs), medical, surgical, and orthopedic devices, automotive parts, precision components, tools, and tooling, molds and dies, blades, and firearms.