Zirconium Nitride, Zirconium Carbonitride, & Zirconium Oxycarbide Coatings

Zirconium-based coatings provide performance characteristics and a broad color palette for many parts and products in diverse industries. These enhance product durability and appearance.

Zirconium-based PVD finishes—including zirconium nitride coatings (ZrN), zirconium carbonitride coatings (ZrCN), and zirconium oxycarbide (ZrOC) coatings—enhance product durability and appearance. Zirconium-based coatings can add excellent performance characteristics and withstand solvents and corrosion. These PVD coatings add hardness and bright metallic colors (even blues!) to your products.

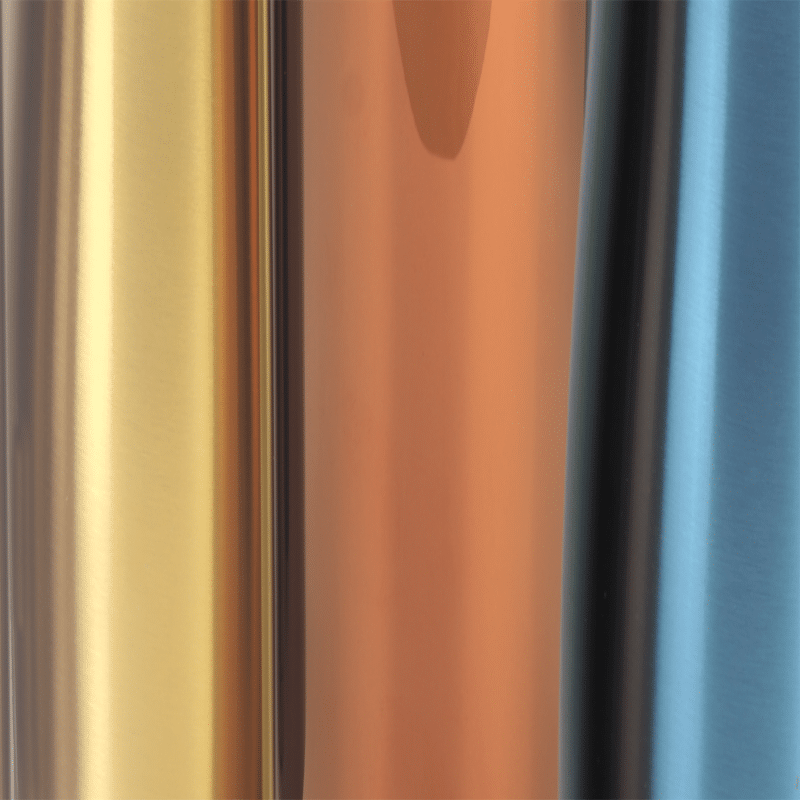

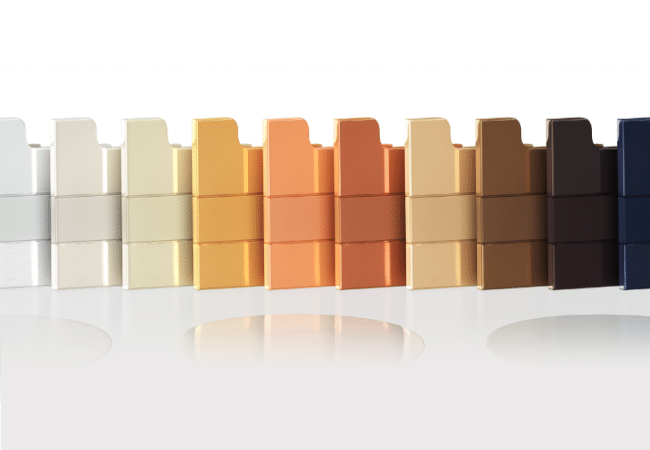

Zirconium-based color PVD coatings

Zirconium is a common material for physical vapor deposition (PVD) coatings. Combining zirconium with various reactive gases creates coatings that mimic the color of nickel, bronzes, golds, silver, and more. In addition, zirconium can produce popular colors not available in any natural metal, such as black and shades of blue.

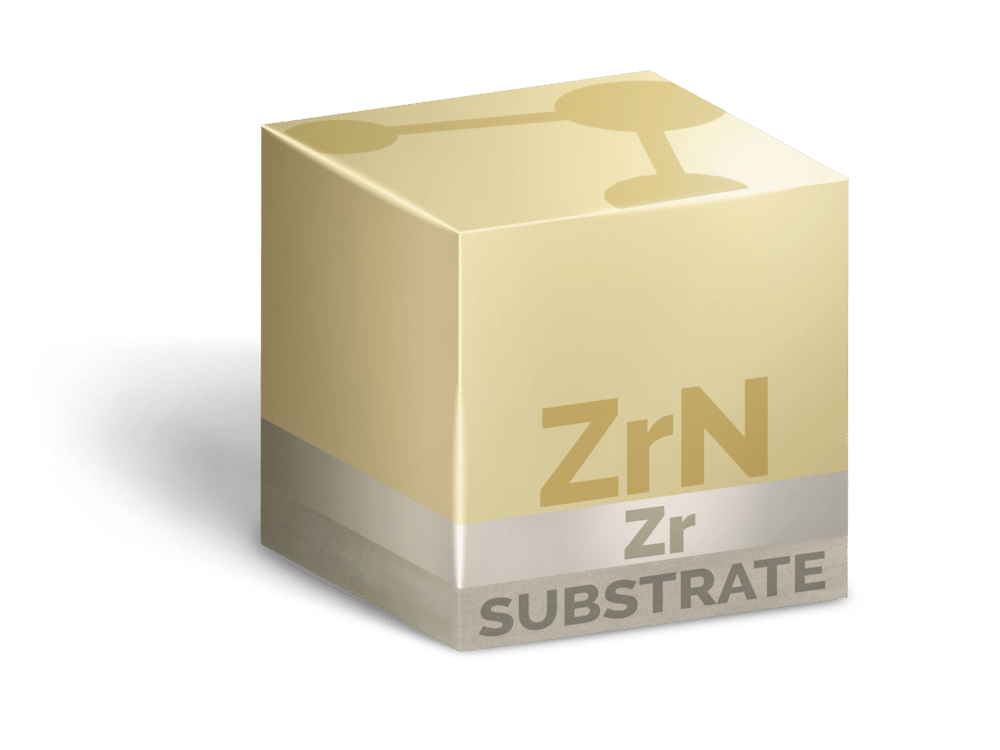

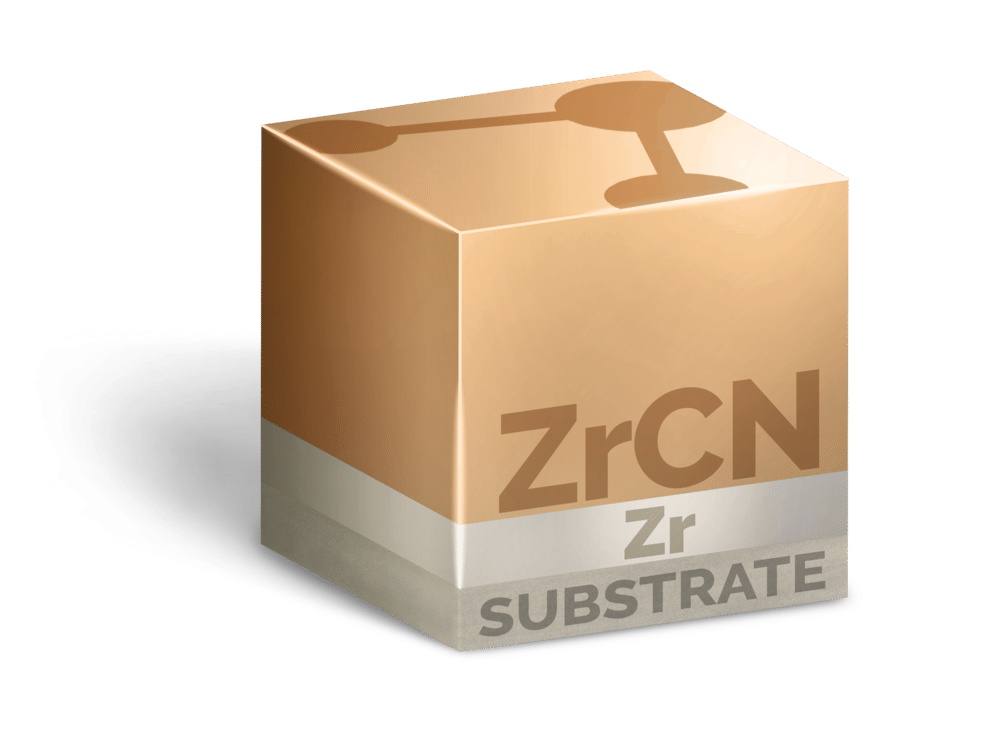

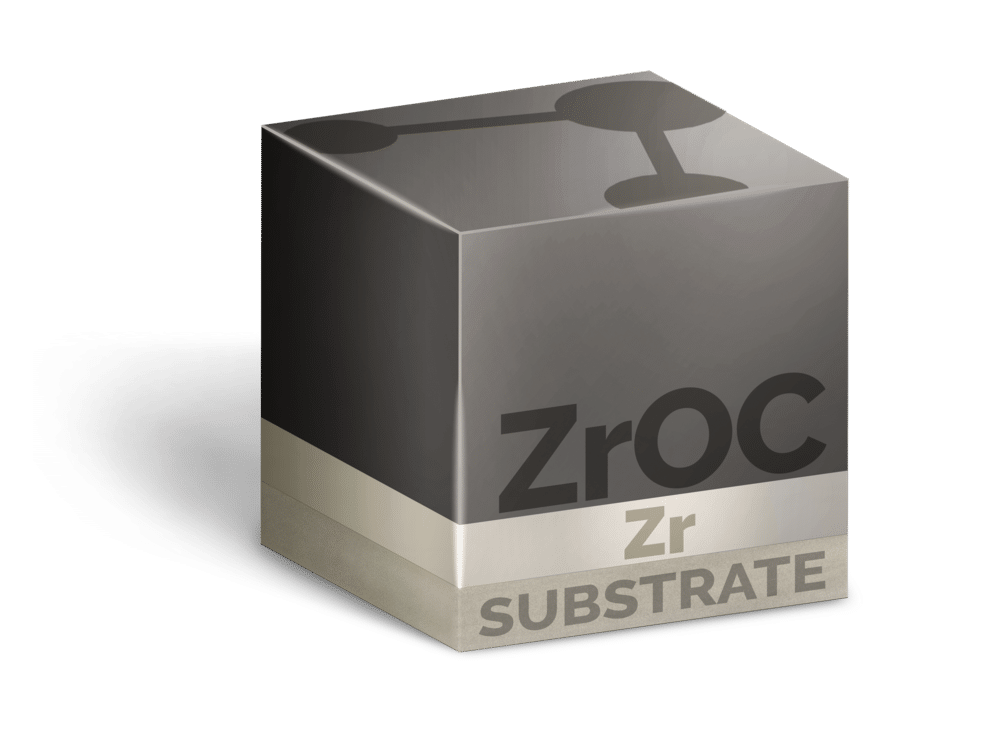

Starting with pure zirconium, we evaporate and ionize the metal in a vacuum chamber while introducing precise amounts of reactive gases such as nitrogen, oxygen, methane, or acetylene to form the compounds that generate these diverse colors.

Adding nitrogen to create zirconium nitride (ZrN) coatings results in yellow tones ranging from nickel to brass. Add carbon-based gas (methane or acetylene) and nitrogen to form zirconium carbonitride (ZrCN) coatings to produce reddish golds and bronzes. Mix oxygen with a carbon gas to form zirconium oxycarbides (ZrOC) that create darker colors, from graphite to black to bronze.

Performance and durability of zirconium nitride and zirconium carbonitride coatings

Zirconium-based coatings are extremely hard. Compared to chrome plating, zirconium-based PVD color coatings are significantly harder and more durable, making them ideal for parts used in high-use or wear applications.

VaporTech coating systems

Get started with the right VaporTech machine, now including the V.MAX1500 system.

Blog post: Zirconium PVD

Zirconium often serves as a PVD base material–there are excellent reasons why.

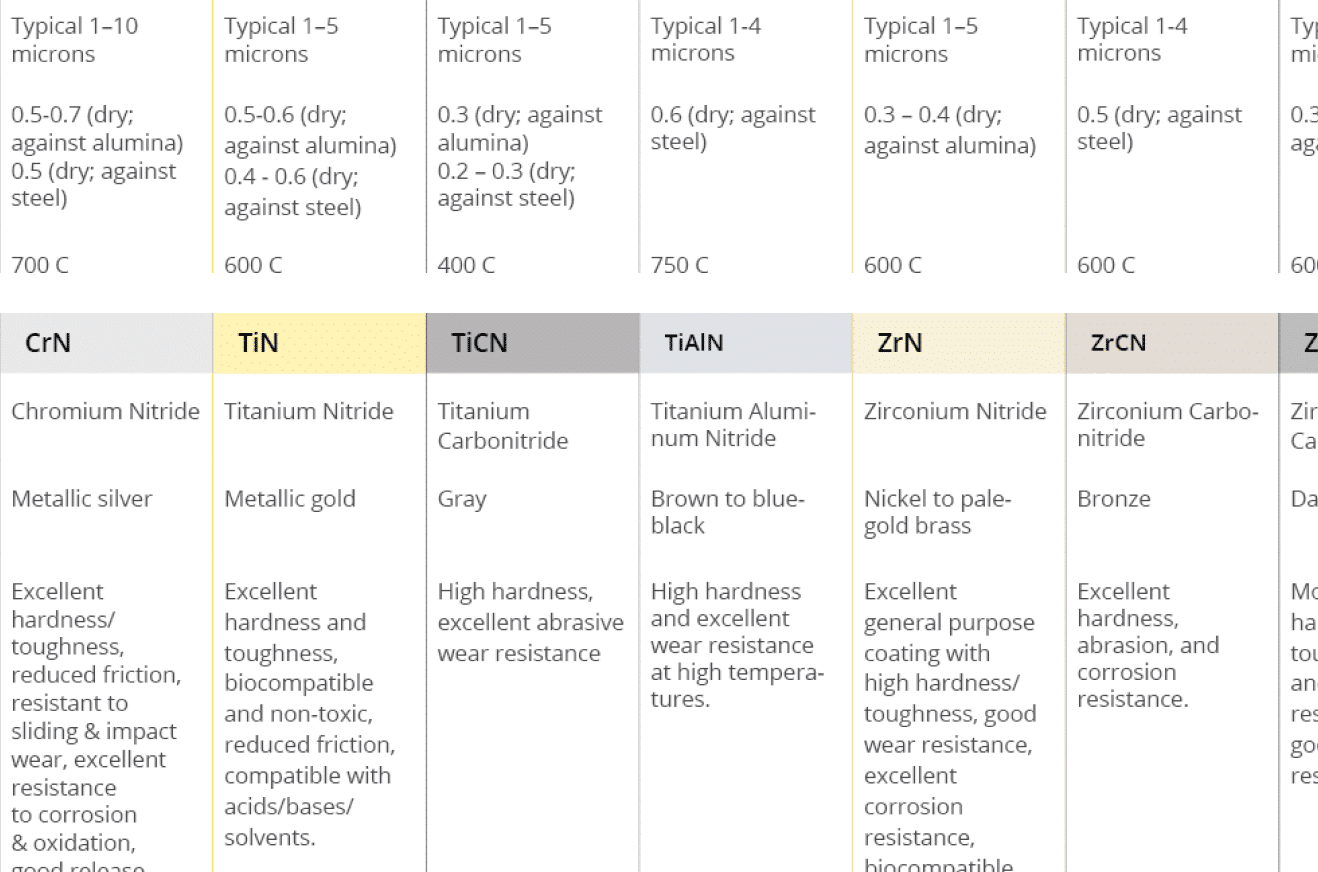

Performance coatings chart

Download a complete chart of DLC and other performance PVD coating properties.