Use Our Zirconium Coating Technologies for Outstanding Durable & Decorative Coatings

Why Use Zirconium-Based Durable/Decorative Color PVD Coatings

When exploring durable/decorative color PVD coatings, you might notice that zirconium often serves as the base material—and there is an excellent reason for that. The initial use of hard PVD coatings for durable, decorative thin films used a titanium base, gold-colored titanium nitride (TiN), to be exact. However, the industry quickly found that zirconium-based coatings provided more value for performance and color palette.

The benefits of zirconium-based PVD coatings

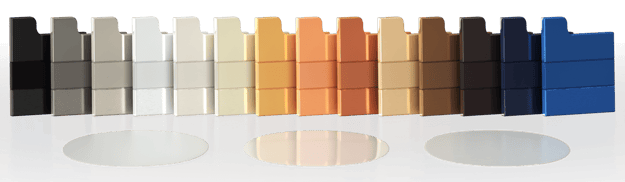

In the late 1990s, polished brass finishes were all the rage in home decor–from door hardware to plumbing fixtures and everything in between. Once scientists discovered that zirconium nitride (ZrN) can imitate natural brass, companies began to research zirconium coating options in earnest. Next came a rush to introduce finishes with lifetime durability guarantees. As with all decorative trends, times change, and soon, metallic finishes like stainless steel and nickel replaced brass as the dominant finish and, more recently, bronzes, rose golds, purples, "rainbow" style, and blacks. Twenty years after the discovery that ZrN imitates natural brass, zirconium is the chameleon metal that can respond to evolving product trends.

Our scientists can formulate zirconium-based coatings to make many PVD colors using the cathodic arc deposition method (LTAVD®) found in VT-series™ PVD coating systems. We start with pure zirconium, evaporate, and ionize the metal in a vacuum chamber while introducing precise amounts of reactive gases such as nitrogen, oxygen, methane, or acetylene to form the compounds that generate these various colors. Adding nitrogen to create zirconium nitride (ZrN) compounds results in yellow tones ranging from nickel to brass.

Add carbon-based gas (methane or acetylene) and nitrogen to form zirconium carbonitrides (ZrCN) to produce reddish golds and bronzes. We can also mix oxygen with a carbon gas to form zirconium oxycarbides (ZrOC) that create darker colors, from graphite to black to oil-rubbed bronze. Simple modifications can make a rainbow of color PVD coatings with a single metal— zirconium!

Performance and durability of zirconium-based coatings

Zirconium-based coatings have exceptional resistance to a wide variety of chemicals, both acids, and alkaline, making them the preferred choice for applications where harsh cleaning chemicals or corrosive environments could damage uncoated parts. These compounds are also very hard. Compared to another well-known durable finish—chrome plating—zirconium-based PVD color coatings are typically 2-3 times harder, making them a durable choice for parts used in high-use areas or exposure to abrasive elements.

About VaporTech

Vapor Technologies, Inc. is a PVD coating machine manufacturer located in Colorado that serves clients worldwide. In addition to our engineering and manufacturing teams, we have an extensive R&D operation, including material scientists working in two distinct and well-equipped labs.

For more information about our zirconium-based coatings and the machines that create them, please contact us today!

Recent posts

All That Glitters is Not Gold—But It May Be Gold PVD Coating

Chrome PVD Coating: an Alternative to Hexavalent Chrome Plating