DLC & PVD Gun/ Firearm Coating Machine System

Firearms and outdoor sports manufacturers, improve your products with in-house PVD and DLC gun coatings and firearms coatings.

DLC and PVD coatings improve the appearance, value, and durability of firearm components including handguns, revolvers, and pistols. These properties explain the coatings’ growing popularity within the firearms manufacturing industry and its respective customers. Applying this thin layer of PVD or DLC coatings to gun components adds hardness to the entire surface, protecting parts from scratches and other forms of wear.

DLC & PVD Coating System for Firearms

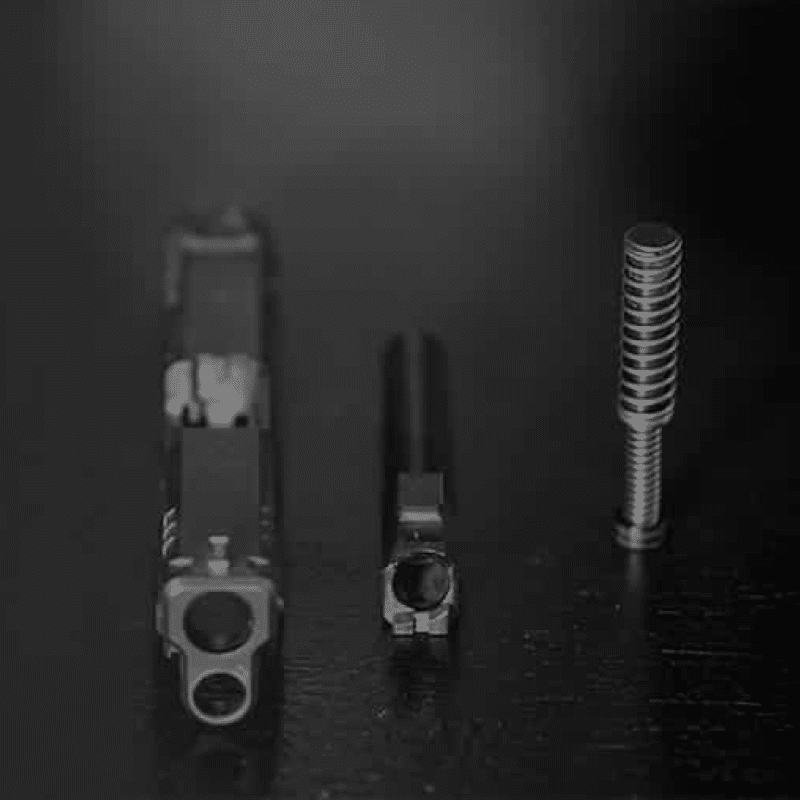

Our DLC & PVD gun & firearm coating machines add a durable, attractive look and performance to gun components. They often coat triggers, sights, frames, muzzles, barrels, and metal framings. Apply these hard physical vapor deposition (PVD) and diamond-like carbon (DLC) firearms coatings through physical or plasma-enhanced chemical vapor deposition (PE-CVD).

Our PVD machines create a distinctive DLC firearms coating for a durable finish in metallic colors. Using VaporTech® PVD & DLC machines for DLC gun coatings means your per-part firearm coating is typically less than $1.

Gun Diamond-Like Carbon Coatings

Our DLC & PVD gun & firearm coating machines apply coatings that are particularly beneficial in coating firearms as they increase durability, reduce sliding friction, are only microns thick, and are effective on various materials. As weapons have precision-machined parts, it is vital to have all sliding mechanisms functioning correctly and minimize resistance and friction. Using DLC gun coating may lead to less need for lubricants and, therefore, less dirt and dust build-up on pistols. Our DLC & PVD gun & firearm coating machines apply DLC (diamond-like carbon) coating to firearms. DLC & PVD coatings for firearms enhance performance and come in distinctive shades of gray to almost black.

Another significant benefit of diamond-like carbon coating guns is the coating’s ability to adhere to various materials and shapes. An industrial PE-CVD system applies the DLC coating on your guns evenly across components, providing durability and a smooth finish to parts including:

- Triggers

- Sights

- Frames

- Muzzles

- Barrels

- Metal framings

Contact us for more information about how we can meet your exact needs.

Answers to DLC questions

Visit our DLC FAQ for details to learn how DLC coatings enhance your products.

Performance coatings

Explore the benefits of VaporTech functional thin-film coatings.

Durable color coatings

The value-added beauty of VaporTech decorative coatings.