PVD Coating Machines for Cutting Tools

Keep your cutting tools hard and sharp longer with PVD coatings applied in-house.

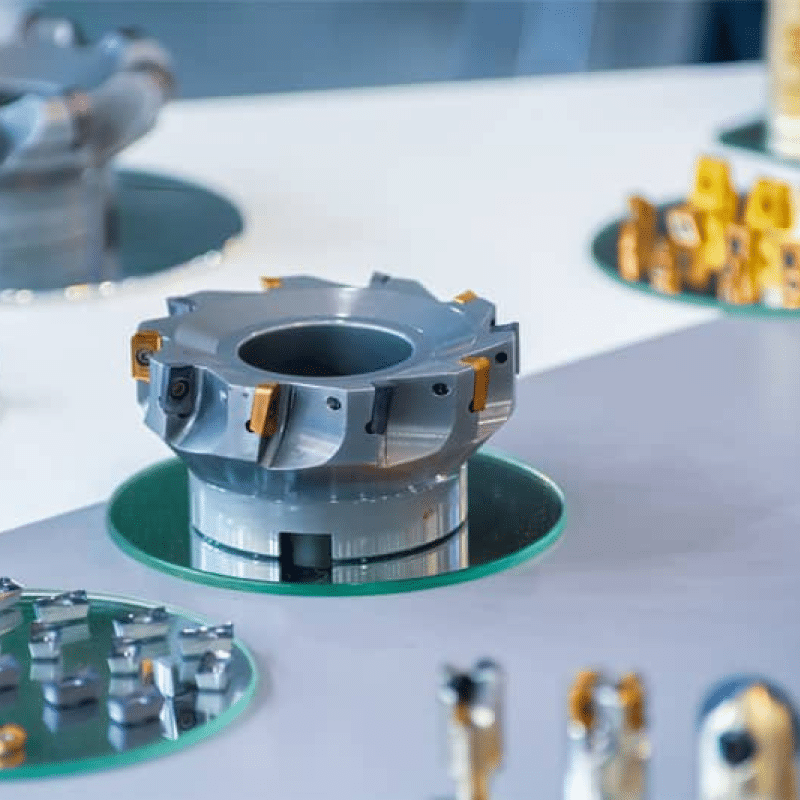

Cutting tools generate significant heat, weakening them and shortening their useful life. Prolong the life of your cutting tools with high-performance functional physical vapor deposition (PVD) coatings. PVD coatings for end mills, slab mills, hobs, inserts, and cutters are designed to reduce friction and protect tools from abrasion and edge buildup.

Get exceptional industrial product coatings in the V.MAX1500 coating system. Learn more »

PVD coating machines for cutting tools

With an in-house PVD and DLC coating machine for cutting tools, you can add hardness and toughness, reduce friction, and provide corrosion and wear resistance. Our experts help you choose the most appropriate coating material and optimize it for your needs, whether for end mills, slab mills, hobs, inserts, or cutters.

PVD coating on cutting tools offers reliability, durability, and performance.

VaporTech® TiN-CrN-DLC coating machine systems keep cutting tools sharper and prolong their usability. In addition, they protect from heat buildup and reduce friction. Depending on your needs, several PVD coating solutions for cutting tools are available:

Titanium nitride (TiN) coating for cutting tools

TiN is the most recognized common PVD coating for cutting tools. It is the bright yellow-gold coating commonly seen on drill bits. Titanium tool coating provides hardness and toughness and reduces friction. TiN is compatible with acids/bases/solvents for applications in which chemicals are used.

Titanium carbide (TiCN) coating machine for cutting tools

TiCN is an excellent PVD coating for high hardness and abrasive wear resistance.

Zirconium nitride (ZrN) coating for cutting tools

Zirconium nitride coatings are excellent general-purpose coatings for cuttings tools, featuring high hardness/ toughness, good wear resistance, and excellent corrosion resistance.

Diamond-like carbon (DLC) coating machine for cutting tools

DLC is an amorphous carbon coating with very low friction, high hardness, resistance to sliding wear, and attractive graphite-to-black color.

Performance coatings

Explore the benefits of VaporTech functional thin-film coatings.

VT-1500i™ system

The VT-1500i is a compact, price competitive, high-capacity PVD coating machine with optional sputtering capabilities.

Cadence system

Quickly deposit coatings that improve your product’s wear resistance and reduce friction.