PVD Medical Device Coating Equipment

Invest in vacuum coating systems for better medical devices, orthopedic and dental implants, and surgical instruments.

Biocompatible PVD coating enhances implant and instrument performance by improving durability, reducing friction, and enhancing corrosion resistance. Titanium and DLC coatings are proven to promote cell attachment and minimize ion release in implants. VaporTech machines that deposit these coatings are cost-effective in-house solutions that lower per-part coating costs and streamline coating processes.

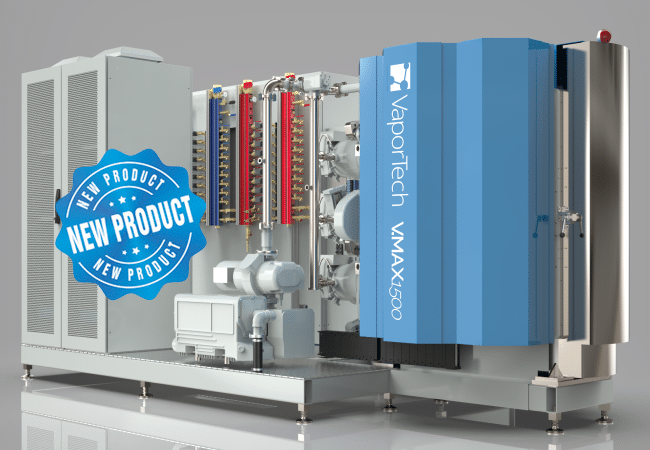

Get exceptional industrial product coatings in the V.MAX1500 coating system. Learn more »

PVD medical device coating equipment for medical, surgical, and implant products

Medical devices require properties not inherent to the base material. PVD coating provides excellent hardness and toughness, biocompatibility, low coefficient of friction, and compatibility with cleaners and other solvents. PVD medical coating technologies add value to:

- Orthopedic implants

- Plates, screws, and tapers

- Guidewires

- Surgical tools

- Blades, scissors, forceps, clamps

- Tableting

- Burs and Diamonds (dental drill bits)

- Handpiece (dental drills)

- Instruments (scalers, curettes, forceps, elevators)

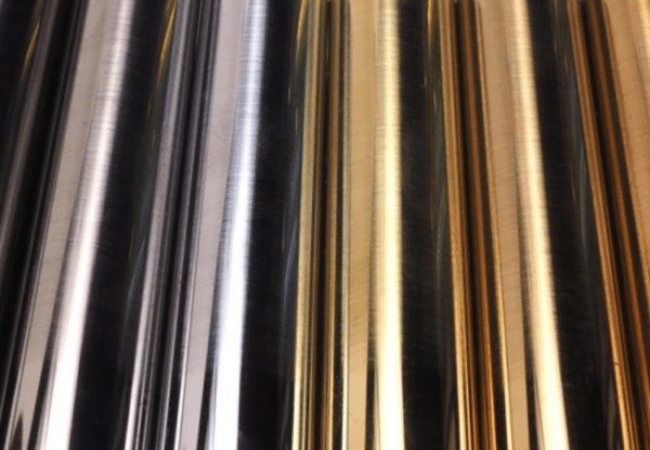

Medical device finishing & coating properties

Our PVD medical coating technologies ensure you get your product’s exact characteristics to make it stand out from its competition. Our systems can coat a wide variety of materials and part geometries. Standard medical device coatings include titanium nitride (TiN), zirconium nitride (ZrN), and diamond-like carbon (DLC).

VaporTech PVD machines for medical devices

VaporTech® PVD medical device coating equipment systems are quick and easy to install and use for manufacturers of orthopedic and dental implants, plates, screws and tapers, guidewires, surgical tools, and items such as blades, scissors, forceps, and clamps. Contact us today for more information about our PVD coating systems for medical devices and equipment.

New: V.MAX1500™ system

Check out our newest PVD coater designed for industrial applications.

VaporTech PVD & DLC coatings

Discover new decorative and performance thin-film coating options that improve your parts and products.

Download system brochure

Read & download detailed VaporTech systems information and specifications.