Coatings Optimized for Your Application

Perfecting the functional properties and appearance of your coating recipes.

Your product is one of a kind and your thin-film coating should be too. Before delivering a coating system, we work closely with each of our customers on a coating optimization program (COP). In this program, we dive into the details of your application including the functional characteristics and appearance you require to improve your product. Our team of thin-film experts customizes your coating process and measures the results (on your actual product) in our on-site materials analytical laboratory. We can also modify the coating process to operate at lower temperatures, improve wear resistance, reduce friction, or create a unique color for your product. After a coating recipe is created for your product, we then offer services to design custom part racking, create coating user guides as a reference for your staff, and visit your site to install and train your manufacturing team on how to apply your thin-film coating on your new VaporTech thin-film coating system.

VaporTech Coating Optimization Programs

include the following:

Coating feasibility

In this phase, we create a new custom coating on test “coupons” for testing and review without consuming production parts.

Coating optimization

The coating process is optimized and verified on your parts in a production coating system.

Production readiness

We finalize the coating process including cleaning, part racking, and quality standards, then capture this information in a coating user guide.

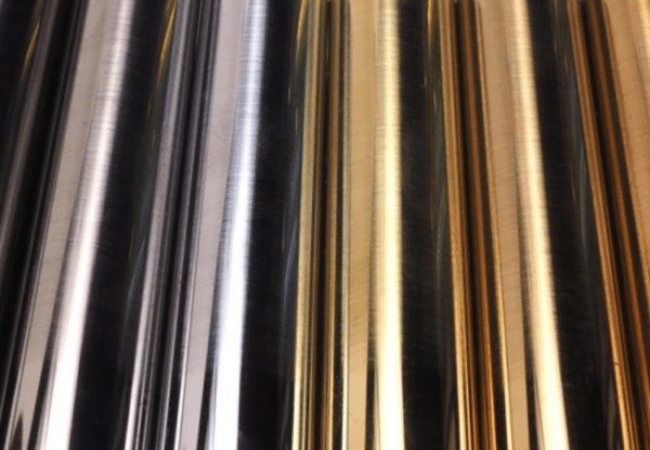

VaporTech PVD & DLC coatings

Discover new decorative and performance thin-film coating options that improve your parts and products.

Installation & training

We help integrate your system into your existing manufacturing operations, install it, and train your people on operation, coating processes, and maintenance.

An ongoing partnership

VaporTech is here for you after your purchase, with technical support, remote and on-site maintenance, parts, and repair services to keep your equipment in great shape for years to come.