Copper Alloys’ Antimicrobial Effects Make PVD Copper Coatings an Ideal Solution

Scientific evidence shows that certain copper metal alloys have antimicrobial properties.1,3,4,5 Studies have also demonstrated that when certain coatings containing these alloys are applied to the surface of products, they can provide antimicrobial protection of the surface.2

VaporTech® has been researching the antimicrobial properties of copper PVD coating for more than five years. Our proprietary antimicrobial coatings are pending approval from the Environmental Protection Agency (EPA).

How are metals like copper antimicrobial?

Copper is an inherently antimicrobial material. Upon contact, ions of copper damage microbe cell membranes and disrupt the internal functions critical to the viability of bacteria, viruses, and fungi.4 While toxic to many microorganisms, copper surfaces are safe to touch. 1 Governments and large corporations have been exploring alternatives to mitigate the cross-contamination of dangerous microorganisms. From household items to mass transit, the search for non-chemical lines of defense has created a new market for copper products.

Benefits of antimicrobial copper PVD coatings

Antimicrobial copper PVD coatings are high quality, wear-resistant, and cost-effective.

Want to hear more about the benefits of copper PVD coatings? Contact us for more information!

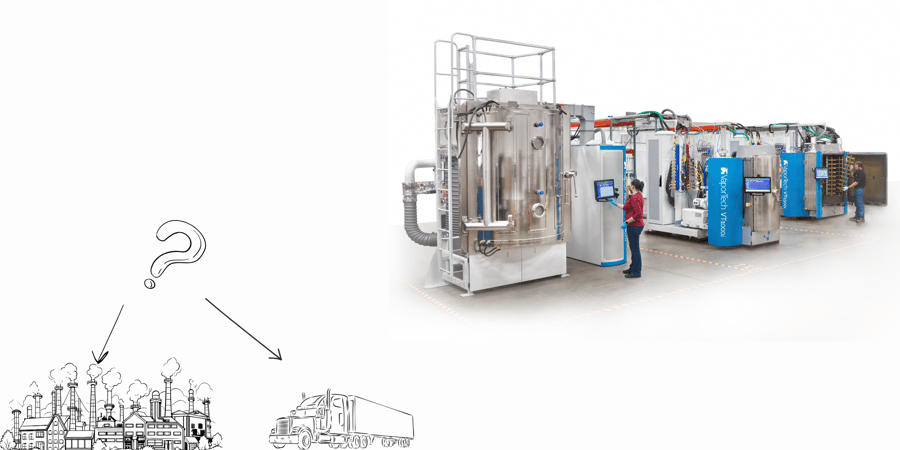

About VaporTech

Vapor Technologies (VaporTech) manufactures PVD systems designed to deposit copper and other PVD coatings engineered to meet your product’s durability, function, and appearance requirements. The coating cost is often less than $20 for an entire chamber load of parts; your current manufacturing staff can operate the system. Email us for more information on how to add value to your products with a new VaporTech PVD system.

Authors note: VaporTech manufactures coating equipment and develops optimized coatings that meet our customers’ aesthetic and functional requirements. Products coated with VaporTech systems must be marketed and sold in conformance with local regulations.

_________________________

1 Borkow, Copper, An Ancient Remedy Returning to Fight Microbial, Fungal, and Viral Infections. Current Chemical Biology, 2009, DOI: 10.2174/187231309789054887.

2 Osés, J.; Fuentes, G.G.; Palacio, J.F.; Esparza, J.; García, J.A.; Rodríguez, R. Antibacterial Functionalization of PVD Coatings on Ceramics. Coatings, 2018, 8, 197.

3 Doremalen, Aerosol and Surface Stability of SARS-CoV-2 as Compared to SARS-CoV-1, New England Journal of Medicine, 2020; 382:1564-1567, DOI: 10.1056/NEJMc2004973.

4 Borkow, Using Copper to Fight Microorganisms. Current Chemical Biology, 2012, DOI: 10.2174/187231312801254723

5 Michels, From Laboratory Research to a Clinical Trial: Copper Alloy Surfaces Kill Bacteria and Reduce Hospital-Acquired Infections. Health Environments Research & Design, 2015, DOI: 10.1177/1937586715592650

Recent posts

In-House PVD Coating vs. Outsourcing: Choosing the Right Solution

The Benefits of PVD Coating on Electroplated Parts