PVD Coating Costs: $20 Per Batch or $20 Per Part? [video]

Does PVD coating add substantial costs to my product?

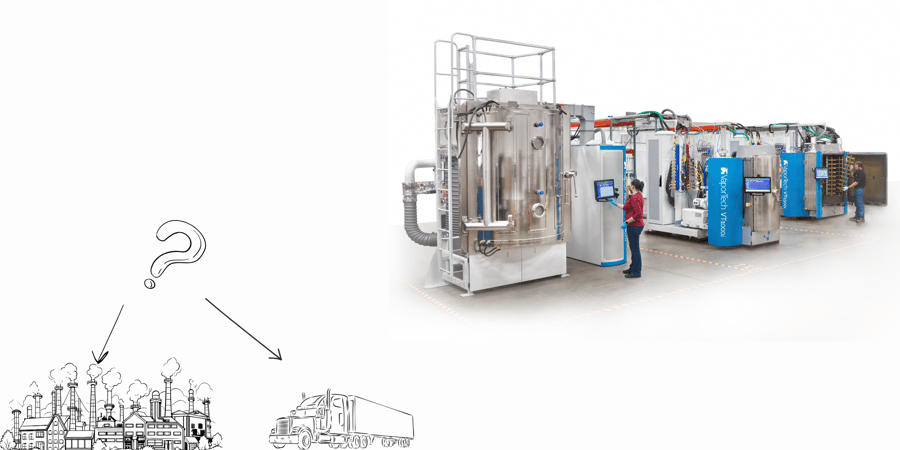

A common misconception about a physical vapor deposition (PVD) finish is that PVD coating costs are high and will add substantial cost to a manufactured part. While having a small volume of parts coated by a coating service vendor can be expensive, the coating cost per part can drop drastically when you purchase PVD equipment and bring the process in-house. VaporTech® manufactures PVD batch coating systems that are capable of quickly coating both small or large volumes of parts. Depending on the part dimensions, our larger coating systems, such as the new VT-3000i™, can coat hundreds of parts in one batch.

Coating costs for decorative PVD applications on consumer products can often be measured in cents, not dollars. Operating a PVD coating system costs include the coating source material, electricity, common gases (such as nitrogen and argon), and periodic maintenance. The source material is often a metal such as zirconium, chromium, or titanium. In many applications, the source material may last for months before the need for replacement. The coating source material is usually the highest-cost consumable. All VaporTech systems use a cylindrical source with a high utilization system, which minimizes wasted material and lowers cost. System maintenance is straightforward and includes only periodic maintenance and cleaning performed by your staff, with more significant maintenance activity with our experts only required annually.

What types of parts can I coat?

VaporTech PVD systems are designed to deposit extremely durable metallic or diamond-like carbon (DLC) coatings on a broad range of consumer and industrial parts. These finishes are incredibly thin, durable, and are available in a wide range of colors. At VaporTech, we work closely with you to understand your product’s characteristics and what you want to improve by applying a PVD or DLC finish. Once a coating type is selected and part dimensions are known, the throughput and cost per batch can be easily estimated. In our experience, many of our potential clients are surprised at how cost-effective adding PVD finishing to manufacturing operations can be.

VaporTech designs, builds, and services thin-film deposition systems that deposit PVD and PE-CVD coatings to improve products worldwide. We’re committed to what we do because we know that a product’s finish instantly communicates its quality—and impacts how your customers view your brand. Contact our team for more information on the feasibility of integrating a thin-film system into your company’s manufacturing operations and lowering your PVD coating costs.

Recent posts

The Benefits of PVD Coating on Electroplated Parts

What is PVD Coating? An Introduction to Physical Vapor Deposition