The Essential Guide to Functional PVD Coatings for Industrial Products

Add hardness, enhance wear resistance, reduce friction, and extend product life with tribological PVD coatings.

What are functional PVD coatings used for?

Tribological PVD coatings enhance a component’s performance by improving its surface properties, thus extending the lifespan of high-wear parts. Materials and gases are combined to achieve desired properties. Common applications include cutting and forming tools, precision components, medical devices, and engine parts.

What functional properties to PVD coatings add to products?

- Hardness (resisting surface damage)

- Toughness (resisting fracture under stress)

- Lubricity (reduces friction)

- Sliding & impact wear-resistance

- Excellent abrasive wear-resistance

- High-temperature wear-resistance

- Corrosion-resistance (against oxidation)

- Compatibility with acids, bases, and solvents.

- Good release properties (against residual stresses)

- Biocompatibility (can be used inside the human body)

What are functional PVD coatings made of?

Many materials are used to create high-performance PVD coatings.

Common functional PVD coatings include chromium nitride (CrN), titanium nitride (TiN), titanium carbonitride (TiCN), Zirconium nitride (ZrN), diamond-like carbon (DLC) and its variants, Zirconium oxycarbide (ZrOC), and titanium aluminum nitride (TiAlN).

Links:

- Functional coatings guide (PDF download)

- Top 5 tribological coatings (blog post)

How do functional PVD systems coat products?

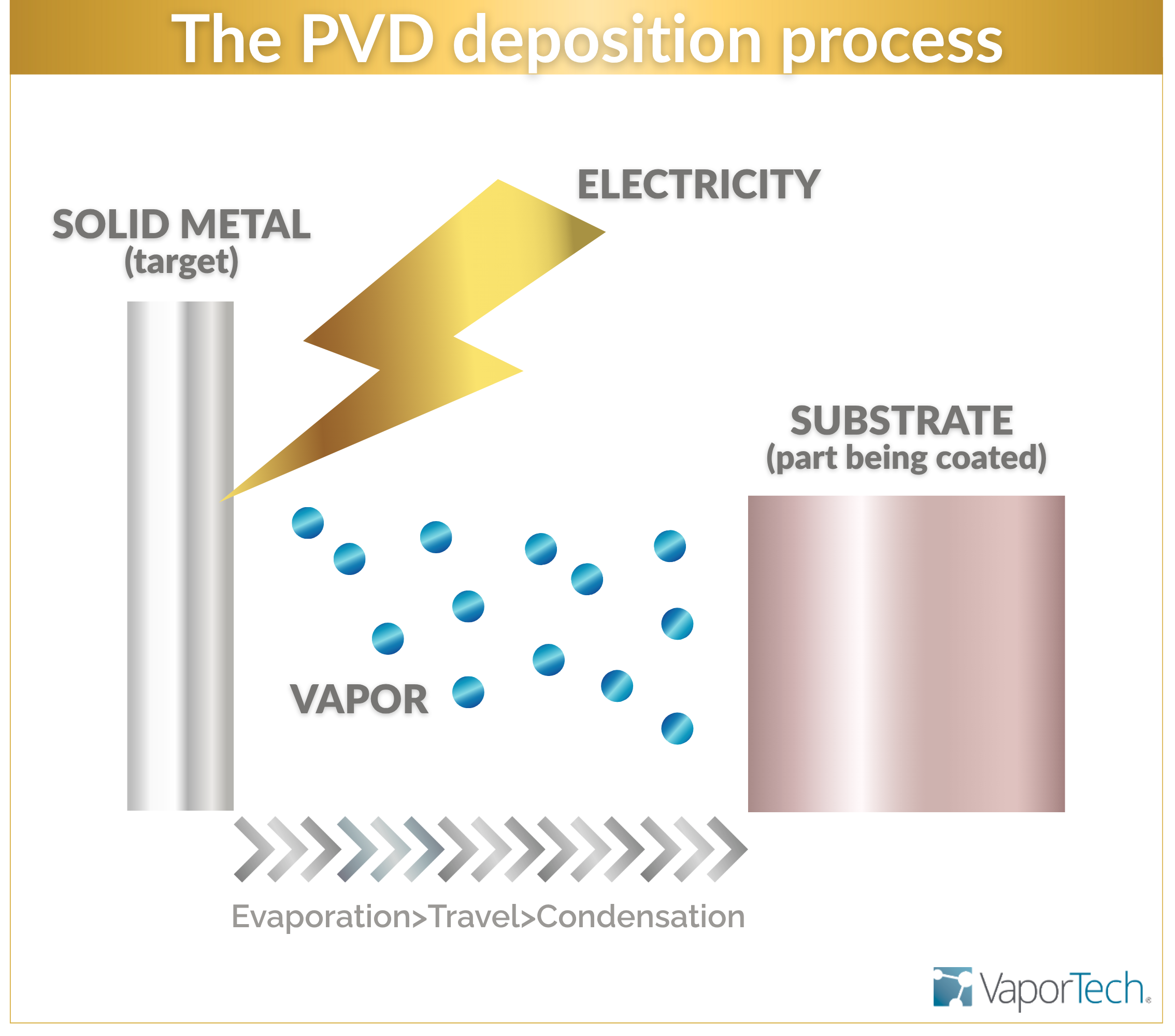

PVD coating technology takes a solid source (called a target) and adds specific inert and reactive gases to deposit coatings. The process takes place in a vacuum chamber, where ionized species (plasma) evaporate material from the target, atom-by-atom. The vapor then deposits on products, creating a protective finish. Functional coatings are usually 1-10 microns thick and require several hours to process in a VaporTech® system.

Which VaporTech coating system is ideal for cutting tools and other high-wear parts?

The V.MAX1500™ batch coater is designed for applications such as cutting and forming tools, precision-engineered components, automotive and aerospace parts, medical devices, and other products that require high hardness, reduced friction, and wear- and corrosion-resistance.

The V.MAX1500:

- Includes six cathodic arc or magnetron sputtering sources that deposit metal-based coatings and a range of DLC coatings.

- Offers heating capability (up to 450°C) to deposit product coatings for extreme environments.

- Is fast and easy to load and maintain, with a removable parts turntable allowing faster loading, unloading, and maintenance.

- Includes plasma nitriding process, which hardens the surface of metal components, combined with PVD coating in a single “duplex” process.

Frequently asked questions

What is coating hardness, and why is it so important?

Hardness is the relative measure of the superficial physical strength of solid material when external mechanical force is applied. It’s the crucial parameter in understanding the structural stability of a coating. Every solid material has a measurable hardness that tolerates a particular amount of external damaging force exerted during cutting, rubbing, grinding, rolling, etc. PVD coating significantly increases hardness over uncoated or plated parts, thereby elevating damage tolerance.

What is TiN coating, and what applications benefit from it?

TiN (titanium nitride) exhibits excellent mechanical, corrosive, and thermal properties, making it suitable for a range of applications. Manufacturers utilize TiN coatings in various industries, including biomedical, automotive, tooling, and outdoor sports. The TiN cubic structure is highly compatible with most metallic substrates, ensuring good coating adhesion on a wide range of substrates. The combination of a non-metallic element (Nitrogen) with a transition metal element (Titanium) forms a refractory (resistant to alteration) material.

What do the various functional DLC coatings do?

DLC coating offers very low friction, high hardness, resistance to sliding wear, and biocompatibility. It’s ideal for automotive components, medical devices, forming tools, and cutting tools. DLC color ranges from graphite to near-black. We can modify the composition and properties of DLC variants by adding small amounts of doping elements, creating many variants to suit specific functional applications.

How do I prep products for functional PVD coatings?

Before placing the substrate inside the deposition chamber, ensure its surface is free of contamination.

Perform media blasting (if required) at lower nozzle pressures and shallow angles to prevent embedding bead material into the substrate.

Substrate polishing before PVD also requires proper cleaning attention. Note that ultrasonic baths (aqueous or vapor degreasers) do not easily remove polishing residue.

Is the V.MAX1500 industrial products coating system hard to use?

Designed for ease-of-use and straightforward maintenance, the V.MAX1500 features a user-friendly interface running our latest VT Coating System software. The removable parts turntable allows faster loading and unloading. The system simplifies routine maintenance, including cleaning, deposition shield replacement, and target changes.

Can I apply functional DLC coatings to any surface (substrate)?

DLC can be applied to most conductive metals. The hardness and surface finish of the substrate influence the coating's durability. The base material plays a crucial role in determining durability, which varies depending on the end-use. As the substrate becomes harder, the combined hardness of the substrate and coating increases.

Will in-house coating bring a return on investment?

Does it make sense for your operation to bring PVD coating in-house? Purchasing a PVD machine is a capital investment that yields very low per-part coating costs, increased manufacturing efficiency, and enhanced quality control. Manufacturers that coat a significant quantity of parts on a regular basis often purchase PVD and DLC coating equipment to bring the process in-house.

Resources & Further Reading

Links:

- VaporTech PVD Coating Equipment (brochure)

- A brief introduction to tribological PVD coatings (blog post)

- Functional coatings for maximum performance (video Q&A)