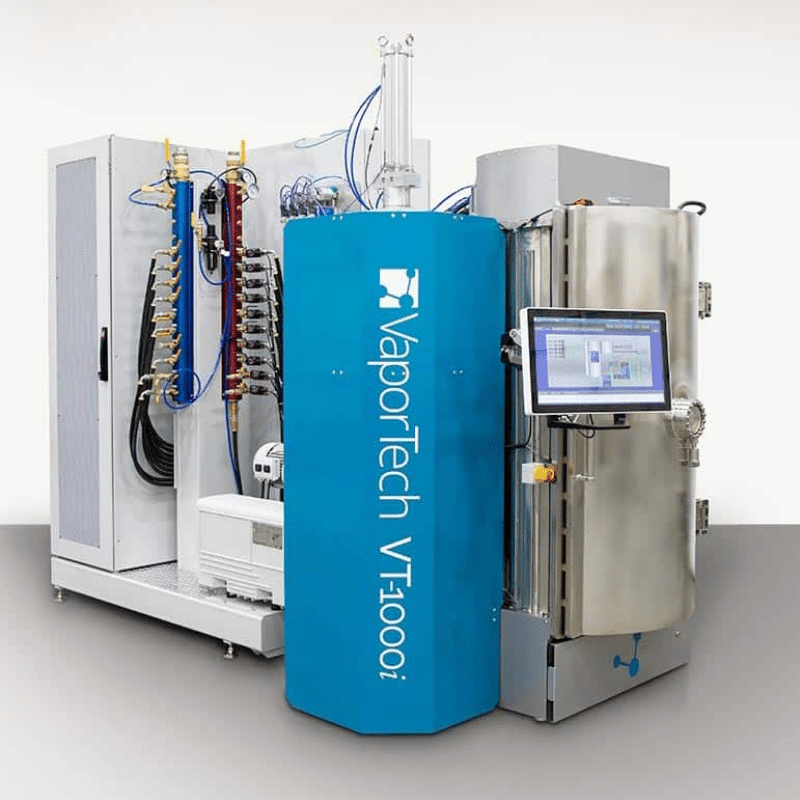

VT-1000i™ System: Easy-to-Operate, Compact PVD & DLC Coating Machine

The VT-1000i™ system is a compact PVD & PECVD/DLC coating machine designed for easy operation. It offers durable color, functional coatings, and diamond-like carbon coatings.

The small VT-1000i™ coating machine is the right-sized PVD and DLC coating system for customers who previously considered thin-film coating systems too complicated or expensive. Differentiate your product by applying the same hard, durable PVD or DLC finishes, which were previously only available to high-volume manufacturing operations, right in your facility.

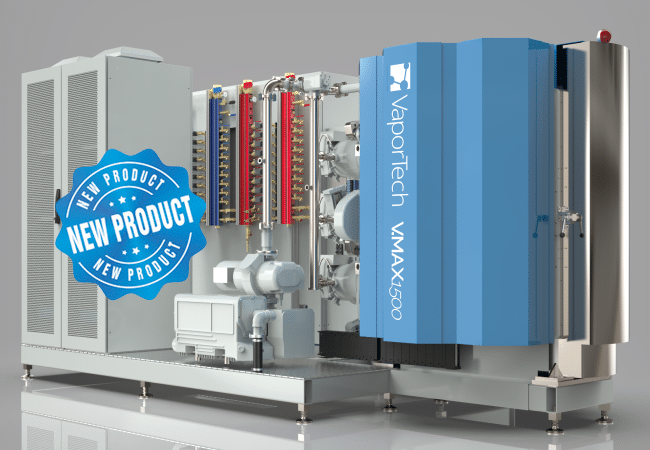

Get exceptional industrial product coatings in the V.MAX1500 coating system. Learn more »

The compact 6-rack design of this small PVD coating machine can deposit a wide range of durable decorative and functional PVD finishes on metal or plated parts, including some plastics. The VT-1000i system is suitable for both small and higher-volume applications, and many parts per batch means a low cost per part and a fast return on investment.

Purchase the VT-1000i compact PVD and DLC coating system, or learn more about our other coating machines by calling (303) 652-8500 today!

The VT-1000i PVD and DLC coating system includes the following key capabilities:

Compact

Small footprint, easy to integrate into factory.

Simple

Easy to operate and maintain.

Low cost

Low per-part coating costs.

Part sizes

Coat large parts up to 100 cm long.

Remote access

Factory remote diagnostics available.

DLC

Durable diamond-like carbon coatings.

| VT-1000i system specifications | |

|---|---|

| System capacity | |

| System footprint | 3.4m x 1.6m |

| Coating area per batch | 4.79m2 |

| Number of racks | 6 |

| Rack size | 100cm x 25.4cm Ø |

| Coating technologies | |

|

|

| Coating processes | |

|

|

| Available coatings | |

|

|

New: V.MAX1500™ system

Check out our newest PVD coater designed for industrial applications.

VT-1500i™ system

The VT-1500i is a compact, price competitive, high-capacity PVD coating machine with optional sputtering capabilities.

VT-3000i™ system

The VT-3000i is our highest-capacity coating machine for large-scale operations.

Looking for a different machine?

- Need a higher-volume option? Take a look at the VT-1500i™ system, our PVD and DLC coating system with optional magnetron sputtering.

- The VT-3000i system is our largest PVD and PECVD/DLC coating machine.

- If you want a compact, fast system for specialty performance applications, check out the Cadence® system.

- Discover the V.MAX1500, a flexible industrial PVD coating system designed for versatility and efficiency in various coating applications.

How big is this coating machine?

The VT-1000i™ system has a footprint of 1.6m x 3.6m (5.2 ft. x 11.9 ft.)

The VT-1000i™ system is the smallest coater in the VaporTech® VTi Series.

How big is the chamber?

The coated area capacity is 4.8m2(51.7sq ft.).

How many racks does this PVD system have?

The VT-1000i™ system has 6 racks.

Which PVD technologies does this system have?

Cathodic arc (LTAVD®)

Which coating processes does this system use?

Physical vapor deposition PVD)

Plasma-enhanced chemical vapor deposition (PECVD) to create diamond-like carbon (DLC) coatings.

What coatings can be applied with this coating machine?

This system applies pure, alloyed, or reacted zirconium, titanium, chromium, and carbon coatings.

What are the industries/applications that benefit from coatings made in the VT-1000i system?

The VT-1000i system coats industrial and consumer products, including plumbing and home hardware products (faucets and doorknobs), medical, surgical, and orthopedic devices, automotive parts, precision components, tools, and tooling, molds and dies, blades, and firearms.