Chromium PVD and CrN Coatings are a Hard Chrome Alternative

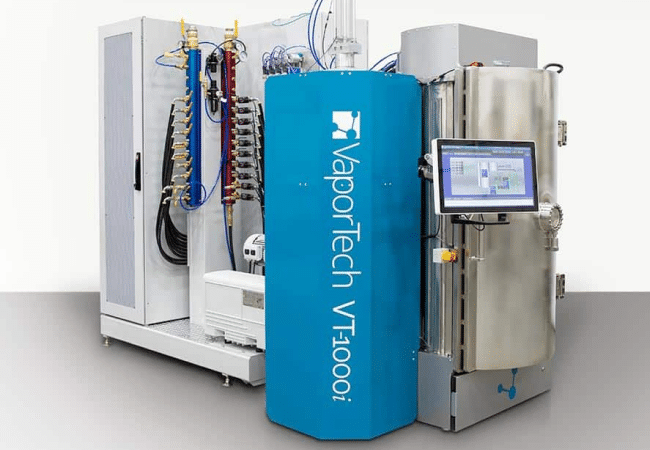

Use VaporTech® PVD machines to safely deposit chromium and chromium nitride (CrN) coatings.

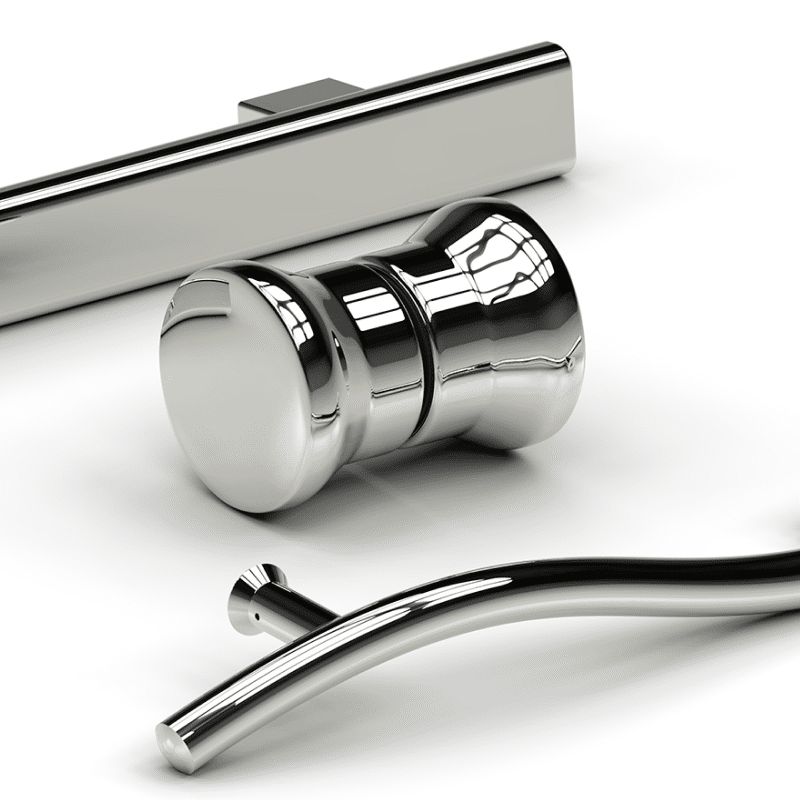

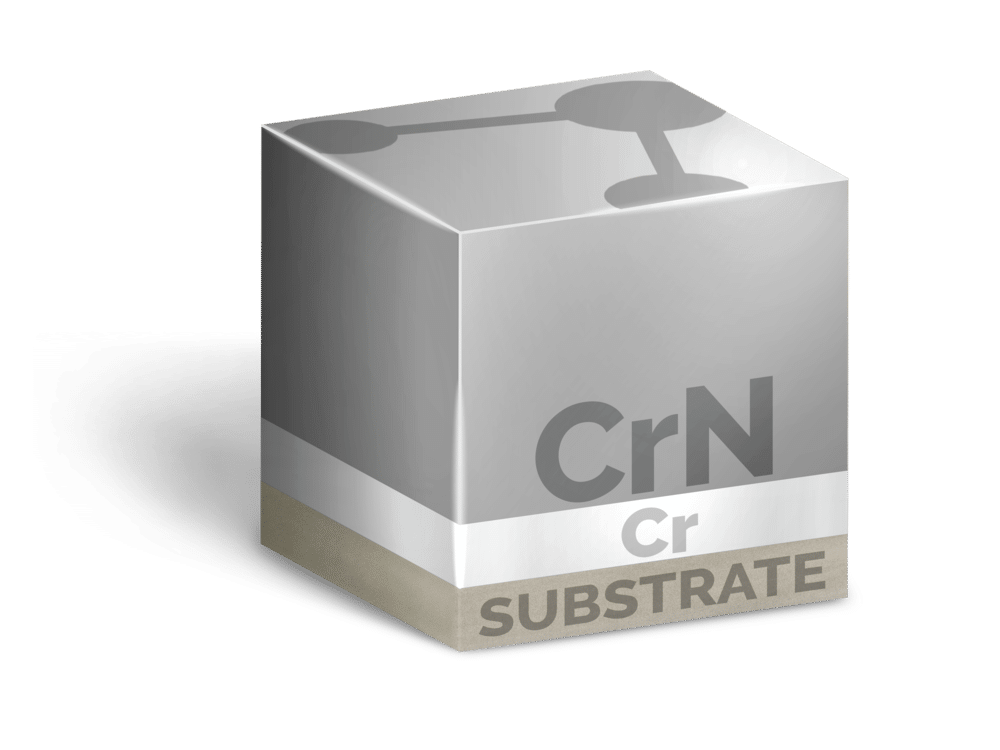

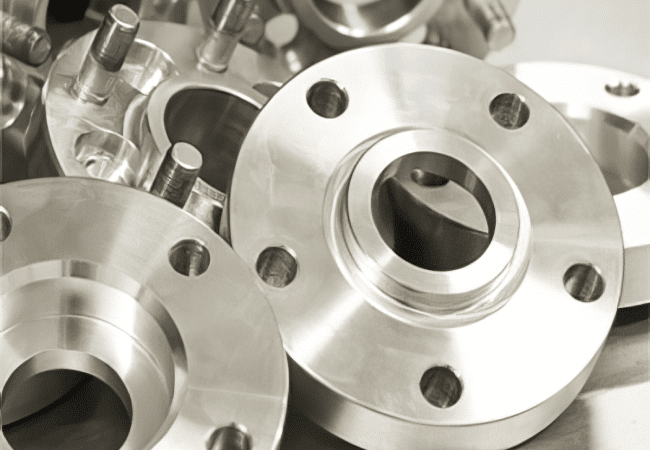

Consumers love chrome: It’s hard, corrosion-resistant, and has a desirable metallic color. The PVD chrome coating process deposits a durable and decorative pure chromium coating that is safe for workers and the environment. Adding elements such as nitrogen can produce more durable PVD chrome alternatives. Chrome Nitride (CrN) coating is exceptionally hard and tough. CrN PVD coating reduces friction, is resistant to sliding and impact wear, has excellent corrosion and oxidation resistance, and is a non-stick option for many materials.

Why manufacturers need PVD chrome coatings for durability, color choices, and wear resistance

Traditional chrome plating exposes parts to chromium baths containing chromium trioxide and sulfuric acid. These chemicals’ toxicity has necessitated investment in safety controls and, in many countries, extensive permitting. To resolve these issues, manufacturers are turning to a chrome alternative.

PVD chrome coating vs. electroplating

- PVD chrome is made of chromium with a color that is virtually identical to chrome plating and is an excellent and non-toxic chrome alternative.

- As a viable chrome alternative option, PVD offers an equivalent hardness (1,000 Vickers) with opportunities to further improve surface hardness (up to 2,200 Vickers).

- Hard-chrome-replacement coatings deposited with PVD equipment provide equivalent or better abrasion resistance.

- Chrome PVD coatings can be designed to meet specific hardness, durability, and corrosion-resistance specifications.

- PVD with a harder chromium nitride base layer improves wear resistance.

Chrome and CrN PVD options that are unavailable with Hex-Cr:

Adding elements such as nitrogen can produce more durable PVD chrome alternatives. Chromium nitride (CrN) improves coating performance in high-wear applications.

A zirconium- or titanium-based durable/decorative PVD coating in a broad range of colors can be applied over PVD chrome.

VaporTech coating systems

Get started with the right VaporTech machine, now including the V.MAX1500 system.

Blog post: PVD chrome benefits

The PVD process offers a chrome coating alternative that is naturally beautiful, durable, and safe.

Detailed CrN information

Explore the benefits of VaporTech PVD and DLC performance coatings.