Diamond-Like Carbon Coating Equipment & the DLC Coating Process

VaporTech® DLC coatings are diamond-like thin-film coatings applied through a plasma-enhanced chemical vapor deposition (PECVD) process.

DLC coatings can be optimized significantly to maximize durability, reduce friction, or improve appearance. All VaporTech diamond-like carbon (DLC) coating systems can be configured to apply both metal-based PVD finishes as well as our durable diamond-like carbon coatings. Our DLC machines apply coatings to machine tooling, engine components, cutting tools, dies and molds, medical devices, outdoor sports, and other high-value products.

Contact us at (303) 652-8500 to learn more about our coating equipment!

Answers to DLC questions

Visit our DLC FAQ for details to learn how DLC coatings enhance your products.

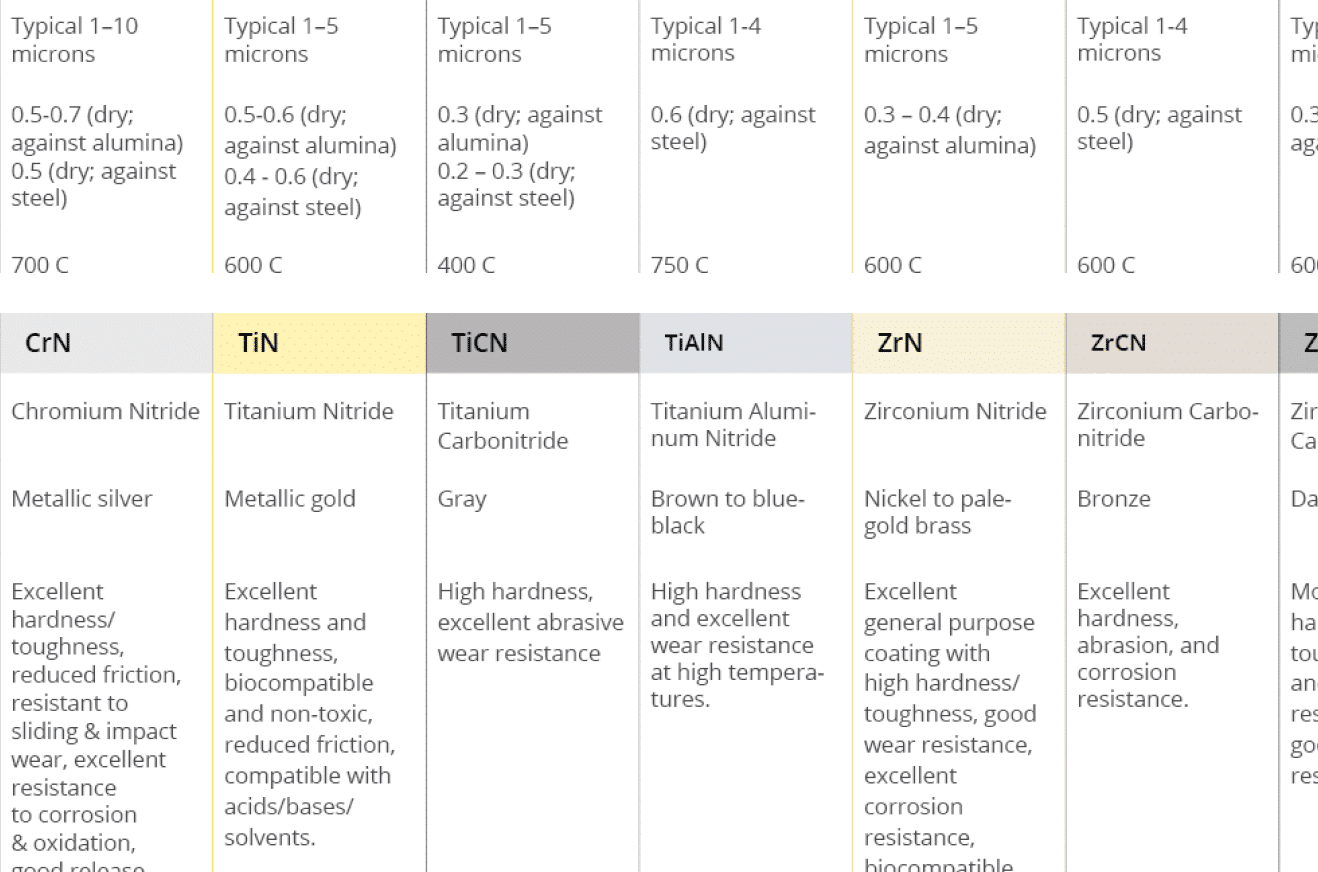

Performance coatings chart

Download a complete chart of DLC and other performance PVD coating properties.

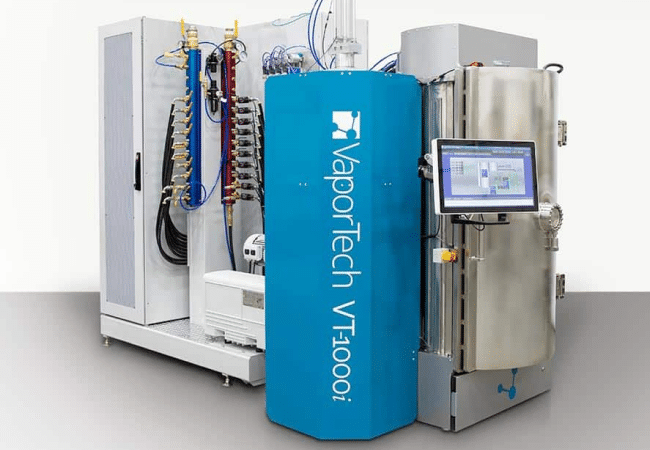

VaporTech coating systems

VaporTech VT-i Series and Cadence thin-film coating systems can support both high- and low-volume coating operations.

Apply diamond-like carbon finishes with our DLC coating equipment

Our DLC coatings feature low friction, excellent wear resistance, and a dark gray to near-black color. The unique VaporTech plasma-enhanced chemical vapor deposition (PECVD) process can coat complex geometries.

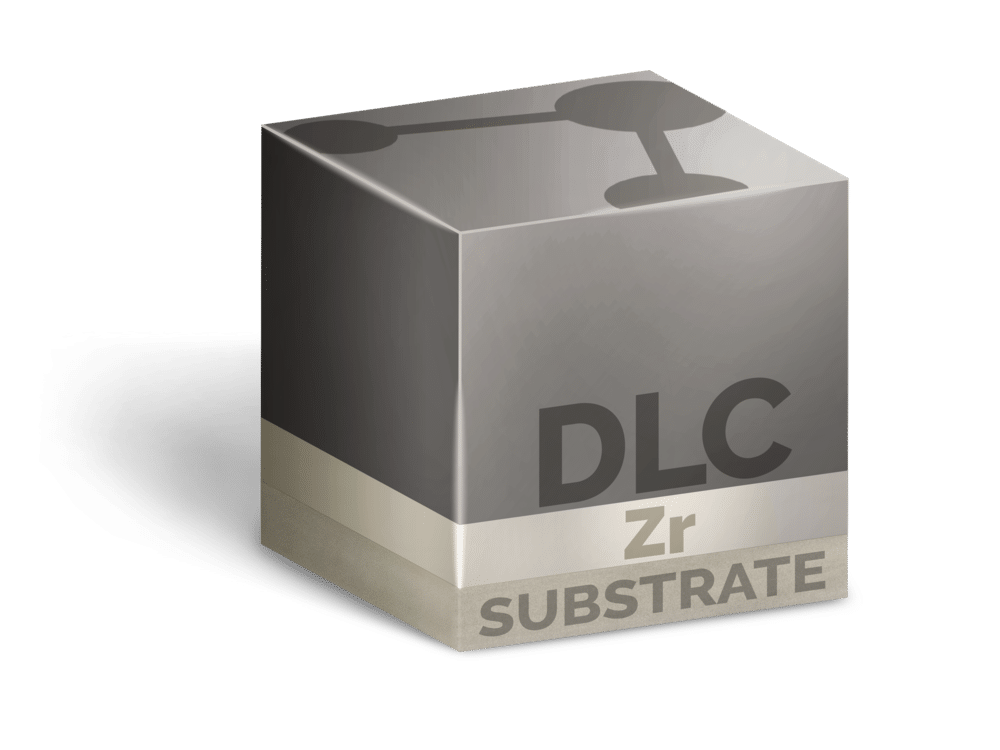

Plasma-Enhanced Chemical Vapor Deposition (PE-CVD), available in all VaporTech® systems, creates our popular VT- DLC (or a-C:H). VT-Series coaters bond this coating to the surface using a Physical Vapor Deposition (PVD) metal adhesion layer of Zirconium (Zr), Titanium (Ti), or Chromium (Cr). DLC coatings combine low friction and high hardness for applications requiring easy release or low sliding wear, like engine components, medical devices, dies, molds and firearms. Moreover, these DLC coating processes create a rich, neutral black color that enhances product appearance and value.

Types of diamond-like carbon coatings available using VaporTech DLC coating systems

DLC (a-C:H DLC)

DLC (a-C:H DLC) is an amorphous carbon coating with very low friction, high hardness, resistance to sliding wear, biocompatibility, and an attractive appearance. It is commonly used for automotive components, medical devices, dies, molds, firearms, cutting tools, sporting goods, and other durable consumer goods. This coating is typically a graphite to black color.

W-DLC (a-C:H:W DLC)

W-DLC (a-C:H:W DLC) is a tungsten-doped amorphous carbon coating. With similar wear resistance to the DLC coating described above, W-DLC offers lower internal stresses, improved adhesion, and more toughness than undoped members of the DLC family. These a-C:H:W PVD coatings are ideal for applications such as gears, bearings, punches, dies, and molds. They come in shades of gray.

DID YOU KNOW?

DLC film friction coefficient against

polished steel ranges from

0.05

to