The Essential Guide to Durable Color PVD Coatings

Enhance and differentiate consumer products with stunning, durable metallic physical vapor deposition (PVD) finishes.

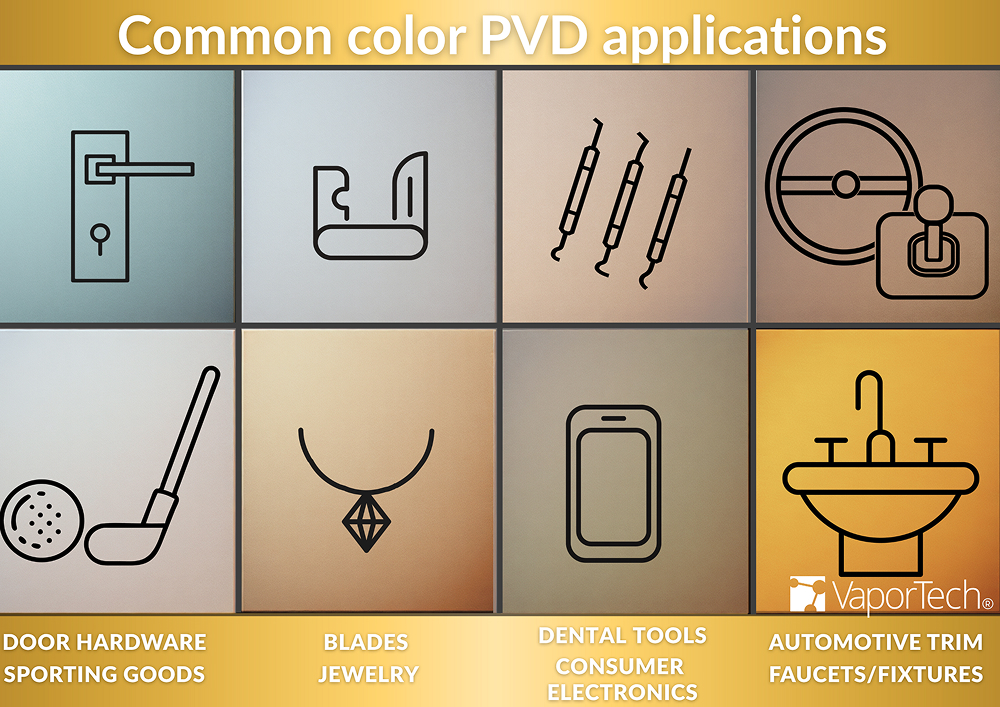

What are color PVD coatings used for?

PVD color coatings enhance both the appearance and durability of products. Manufacturers add these coatings to products ranging from faucets and other home products to automotive trim, sporting goods, surgical tools, consumer electronics, and jewelry. These coatings come in a wide range of metallic colors, including shades of black, graphite, chrome, stainless steel, nickel, gold, copper, bronze, and blue. In addition to stunning colors, PVD coatings provide excellent wear and corrosion resistance.

Color PVD coatings are used on many consumer products and to differentiate medical devices and machine tooling. Applications include:

- Plumbing products & door hardware: Faucets, bath fixtures, doorknobs, and appliance/furniture trim

- Automotive: Interior and exterior trim

- Medical and dental devices: Used to differentiate surgical and dental tools and instruments.

- Outdoor sports products such as golf clubs, knives and blades, and firearms.

- Other applications for color PVD coatings include consumer electronics and jewelry.

What colors do PVD coatings come in?

VaporTech® machines include coating “recipes” for standard colors that can be adjusted to meet product requirements.

Black

Cool Graphite

Graphite

Chrome

Stainless Steel

Nickel

Gold

Rose Gold

Dark Copper

Light Bronze

Bronze

Dark Bronze

Blue Black

Vivid Blue

Purple

Can I get a rich black metallic PVD finish?

To meet consumer demand, VaporTech systems create coatings in dark black, blue-black, graphite, and shades of gray. Our black PVD coatings look beautiful and add a durable layer of protection to parts and products. Common black PVD applications include faucets, doorknobs, and other fixtures, interior and exterior automobile trim, medical devices, blades and firearms, and other consumer products such as luxury watches.

Links:

Which PVD coating machines should I use to apply metallic colors?

VaporTech i-Series™ PVD coating systems are right-sized, competitively priced, high-quality PVD machines have been coating consumer products for more than 30 years.

i-Series systems:

- Deposit both PVD and DLC coatings in the same chamber.

- Use a lower temperature cathodic arc process (LTAVD®) to coat metal and plated plastic parts with a thin, uniform color.

- Are designed for simple maintenance and a low coating cost per batch.

Links:

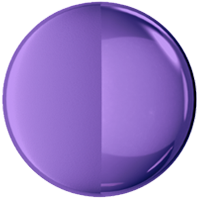

How are PVD coatings made?

Most PVD color coatings are zirconium-, titanium-, or chromium-based. The PVD coating process uses one of these metals as a solid source (called a target) and adds specific inert and reactive gases to deposit coatings.

The PVD process takes place in a vacuum chamber, utilizing ionized species (plasma) to remove material from the target, atom-by-atom. The coating is then deposited on products, creating a thin, bonded metallic finish.

Links:

- A brief introduction to deco coatings (short video)

- The benefits of zirconium-based color PVD coatings (blog post)

How much does in-house color PVD coating cost?

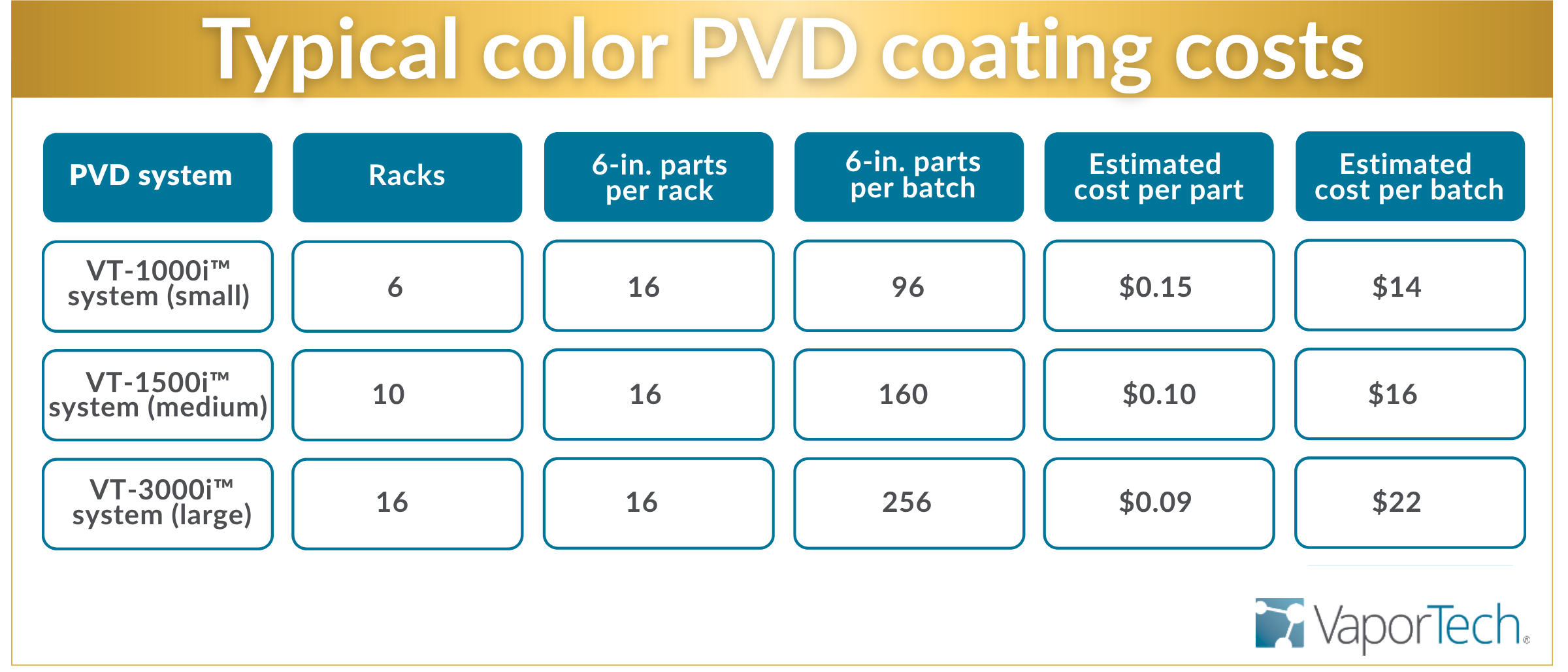

This chart estimates a typical coating cost-per-part for a durable decorative finish, including all consumables. Consumables include electricity, metal “target” material used for coating, and process gases.

Frequently asked questions

How big are VaporTech systems?

VaporTech offers a range of systems tailored to your specific needs. Each system is versatile, capable of utilizing various processes to meet unique coating requirements. VaporTech systems support multiple coating types, materials, and recipes, accommodating both large and small production runs. Our largest system is capable of coating parts up to 48 in. (1.2 m) long.

How long does it take to run a typical batch?

A typical batch requires 1-2 hours for a durable decorative finish and 2-3 hours for a performance wear coating, meaning you can run multiple batches (2 to 6+) in a single work shift. You can clean parts for the next batch and rack them while coating the first batch, minimizing unloading and loading times for high-volume operations.

What’s the difference between cathodic arc and sputtering technologies?

Cathodic arc deposition is a high-energy, high-ionization process. This process enables easy control of reactions at lower temperatures and is ideal for durable/decorative color PVD coatings. Sputtering allows for the use of multiple source materials and creates a thinner coating with fewer defects. It is more commonly used for functional applications, although our beautiful deep black chromium carbide coating is deposited via magnetron sputtering.

Why is zirconium the most used color PVD source?

Zirconium coatings provide the broadest range of durable PVD colors, from stainless steel to brass, nickel, bronze, black, and blue. These “lifetime finishes” resist wear as well as harsh chemicals and abrasives. Titanium and chromium are also used to produce even more color options.

Can PVD coatings deposit gold and rose gold?

One of the most frequent questions we get asked about our decorative PVD offerings is if it is possible to match the appearance of real gold (both white gold and rose gold) with our durable coatings. Our VaporTech® coating systems produce a wide variety of gold-like finishes to meet your needs for a wear-resistant version of gold.

Can PVD coatings produce vibrant PVD colors like purple, rainbow, or a rich black?

One of the prominent trends in product colors is the rise of bold and vibrant hues. Dark black, purple, and rainbow PVD coatings are becoming increasingly popular in consumer applications. VaporTech machines excel at depositing these bright colors.

Learn more about color PVD coatings with these resources from VaporTech.

Links:

- Read the VaporTech brochure (or download the PDF here).

- Durable/decorative PVD color coatings (30-minute webinar recording)