PVD Coating Machines for Engineered Components

PVD and DLC coatings protect your precision machinery parts to improve their function and longevity.

Increase the service life of your precision components with low-friction, corrosion- and wear-resistant physical vapor deposition (PVD) and diamond-like carbon (DLC) coatings. VaporTech® industrial DLC coating systems for engineered parts provide the industrial finishes you need to protect your critical components.

Get exceptional industrial product coatings in the V.MAX1500 coating system. Learn more »

Durability, reliability, and performance

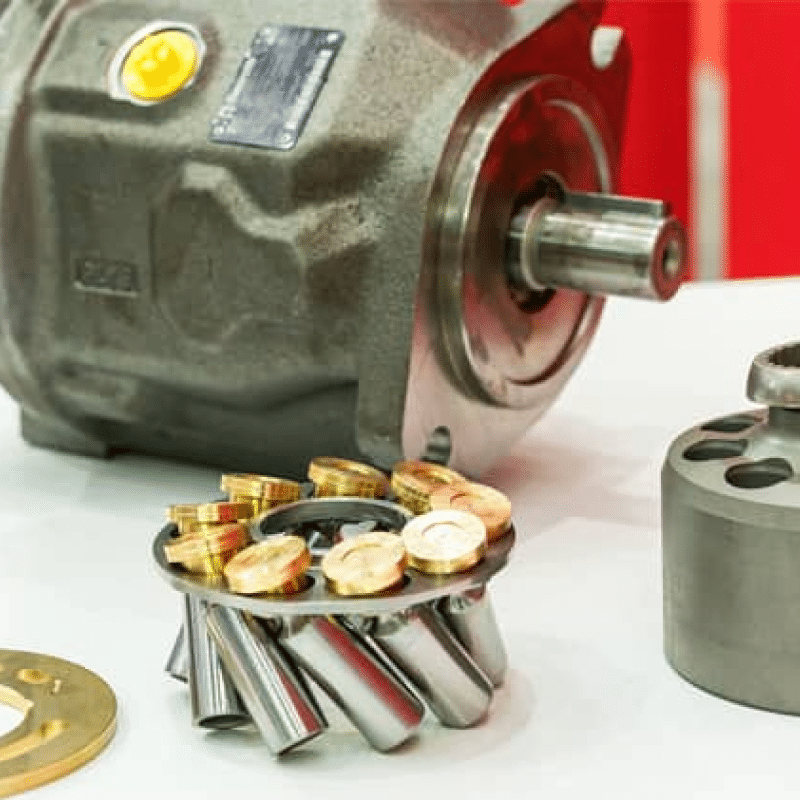

Functional PVD coatings improve engineered components’ durability, reliability, and performance. If your products perform under pressure, PVD coatings protect them from heavy wear and surface fatigue to extend their useful life. Maintain the surface of your parts with these microns-thick coatings. VaporTech® PVD coating machines for engineered components apply PVD coatings for precision components, including:

- Compressor rotors

- Bearings and casings

- Pump rods/pistons/gears/vanes/lobes

- Ball/needle/gate valves

- Hydraulic pistons/rings/rods/actuators

- Assembly line locating and welding pins

Apply PVD and DLC coatings to your engineered parts.

PVD and industrial DLC coatings can be deposited in the same VaporTech® machine. These coatings provide effective solutions for precision parts, including compressor rotors, pump rods/pistons/gears/vanes/lobes, ball/needle/gate valves, bearings and casings, gears, hydraulic pistons/rings/rods/actuators, assembly line locating, and welding pins.

If your components are subject to metal-metal interaction or high-speed or low-lubricity repetitive friction, PVD and DLC coating can help. Having in-house, compact PVD coating systems for engineered components lessens supply-chain headaches and improves quality control. To learn more about coating your engineered components, contact us today!

Performance coatings

Explore the benefits of VaporTech functional thin-film coatings.

VT-1500i™ system

The VT-1500i is a compact, price competitive, high-capacity PVD coating machine with optional sputtering capabilities.

Cadence system

Quickly deposit coatings that improve your product’s wear resistance and reduce friction.