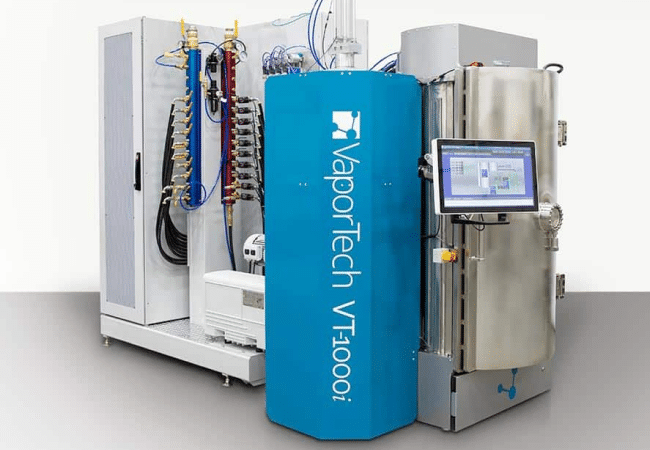

VT-3000i™ System: Highest-Capacity Cathodic Arc Coating Machine

The VT-3000i™ system is our largest PVD and PECVD/DLC coating system delivering our largest chamber and high throughput for large operations.

The VT-3000i PVD coating machine is a large PVD and DLC/PECVD coating system for high throughput or larger parts up to 122 cm (48 in).

Get exceptional industrial product coatings in the V.MAX1500 coating system. Learn more »

Our unique centrally mounted cathodic arc deposition source ensures you get consistency and maximum control over coating uniformity and properties. Lower temperatures enable you to coat various materials such as steel, brass, zinc, or prepared plastic, giving products made of multiple materials a common finish and appearance. Additionally, VaporTech will optimize coatings to meet your specifications for color or function.

Contact us at (303) 652-8500 today to learn more about how our PVD coating systems can save you money while taking your business to the next level!

The VT-3000i PVD coating machine includes the following key capabilities:

Uniform

Excellent color uniformity & deposition rates throughout the chamber.

Flexible

Multiple coating technologies for various applications in a single system.

Consistent

Even coating deposition rates throughout the chamber.

Low temperature

Lower-temperature process suitable for both metal and plastic parts.

Part sizes

Coat large parts up to 122 cm (48 in) long.

Remote access

Factory remote diagnostics available.

| VT-3000i system specifications | |

|---|---|

| System capacity | |

| System footprint | 4.3m x 3.6m |

| Coating area per batch | 12.44 m2 |

| Number of racks | 16 |

| Rack size | 45cm x 20.3cm Ø |

| Size | |

| Height | 150 in. (3.8m) |

| Width | 141 in. (3.6m) |

| Depth | 170 in. (4.3m)* |

| Coating technologies | |

|

|

| Coating processes | |

|

|

| Available coatings | |

|

|

V.MAX1500™ system

Check out our newest PVD coater designed for industrial applications.

VT-1500i™ system

The VT-1500i is a compact, price competitive, high-capacity PVD coating machine with optional sputtering capabilities.

VT-1000i™ system

The VT-1000i is a compact higher-capacity system for medium-sized operations.

Looking for a different machine?

- Learn about the VT-1000i system, our medium-volume compact PVD and PECVD/DLC coating machine.

- Need a higher-volume option? Take a look at the VT-1500i™ system, our PVD and DLC coating system with optional magnetron sputtering.

- If you want a compact, fast system for specialty performance applications, check out the Cadence® system.

- Discover the V.MAX1500, a flexible industrial PVD coating system designed for versatility and efficiency in various coating applications.

How big is this coating machine?

The VT-3000i™ system has a footprint of 4.3m x 3.6m (14.01 ft. x 11.81 ft.)

The VT-3000i™ system is the largest coater in the VaporTech® VTi Series.

How big is the chamber?

The VT-3000i™ system has a coating area capacity of 12.44m2 (40.81 sq ft.)

Which PVD technologies does this system have?

Cathodic arc (LTAVD®)

Which coating processes does this system use?

Physical vapor deposition (PVD)

Plasma-enhanced chemical vapor deposition (PECVD) to create diamond-like carbon (DLC) coatings.

What coatings can be applied with this coating machine?

This system applies pure, alloyed, or reacted zirconium, titanium, chromium, and carbon coatings.

What are the industries/applications that benefit from coatings made in the VT-3000i system?

The VT-3000i system coats industrial and consumer products, including plumbing and home hardware products (faucets and doorknobs), medical, surgical, and orthopedic devices, automotive parts, precision components, tools, and tooling, molds and dies, blades, and firearms.